In this example, Easy platinum plumb solder was removed from its container and placed on a solder plate, making it ready for use. There is also water on the solder plate. The water helps weigh the solder down so it will not blow away when a torch is applied to the joint.

span.customP{text-align:left; float:left; margin-bottom:.5em;}span.bullets{background-image: url("/images/bg-list-bullet-large_1356032862748.png"); background-size:6px; background-repeat: no-repeat; background-position:3% 25%;text-align: left;margin: .5em 0 0 .5em;padding-left:40px; display:block; clear:both;}

Unlike other solders used for platinum repair and fabrication, plumb solder contains platinum. There are three main types of platinum plumb solder – Easy, Medium and Hard. Each type has a different amount of platinum, which affects the melt/flow temperature range: Easy contains about 90% platinum and melts/flows from 1300°C to 1400°C Medium contains about 92.5% platinum and melts/flows from 1400°C to 1500°C Hard contains about 95% platinum and melts/flows from 1500°C to 1600°C

Unlike other solders used for platinum repair and fabrication, plumb solder contains platinum. There are three main types of platinum plumb solder – Easy, Medium and Hard. Each type has a different amount of platinum, which affects the melt/flow temperature range: Easy contains about 90% platinum and melts/flows from 1300°C to 1400°C Medium contains about 92.5% platinum and melts/flows from 1400°C to 1500°C Hard contains about 95% platinum and melts/flows from 1500°C to 1600°C

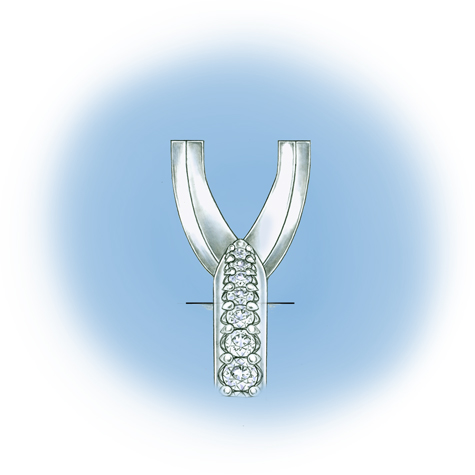

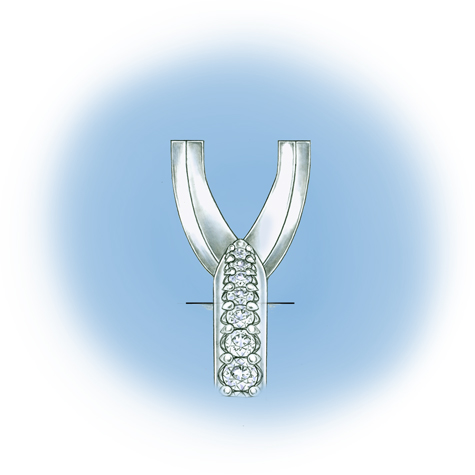

Platinum plumb solder provides a color match that’s superior to repair solders that do not contain platinum

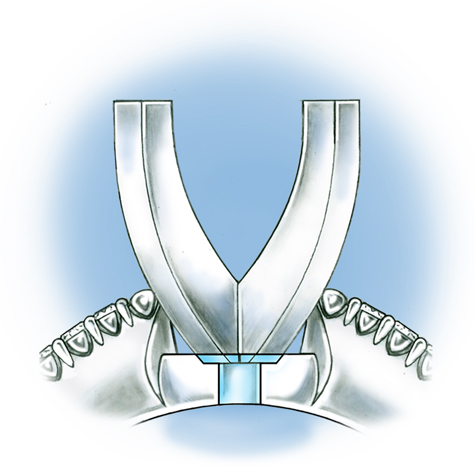

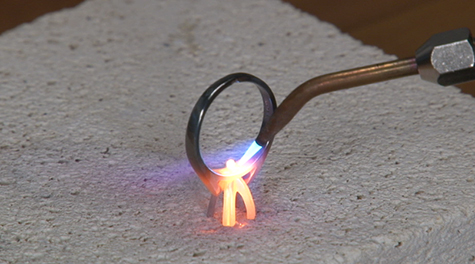

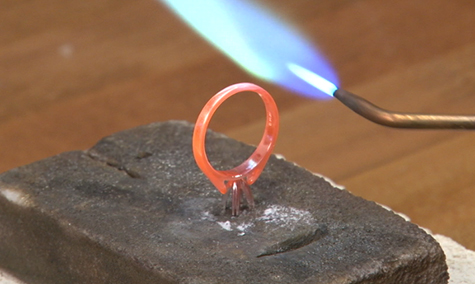

Platinum soldering works best when a pallion of solder is placed over the joint. Do not heat it into a ball for transfer using a solder pick.

Store platinum plumb solders in dedicated, labeled containers. Leaving them exposed causes contamination.

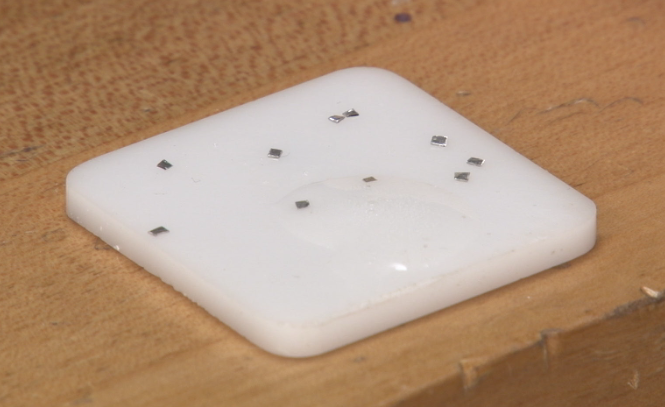

Because platinum calls for high heat to solder, anneal, and work, platinum-specific soldering blocks are required

This high-heat ceramic material block should only be used for platinum soldering projects. Using it with other metals can lead to contamination if it is used with platinum.

The ceramic material is stable. Thermal expansion of the block will be minimal.

The surface of the block is heat-reflective, which helps the heat to intensify sufficiently for the project