Sizing Down Platinum Rings

Sizing Up Platinum Rings

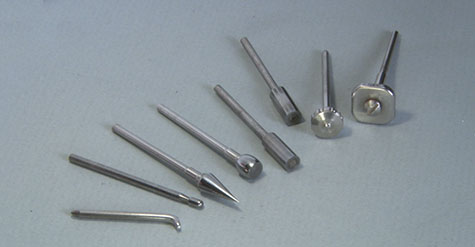

Additional Topics

Burnishing platinum jewelry to remove gouges and scratches

play