Sizing Down Platinum Rings

Sizing Up Platinum Rings

Additional Topics

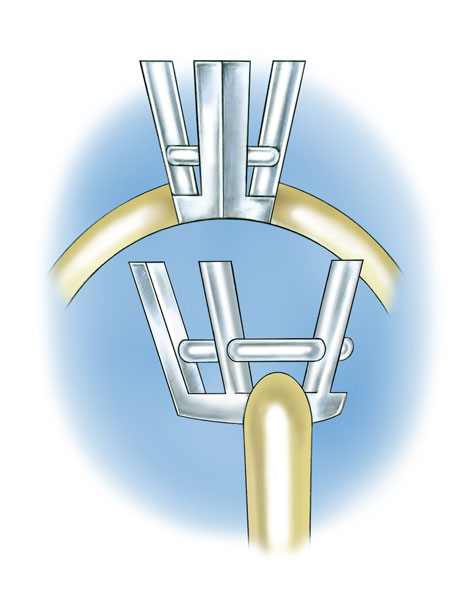

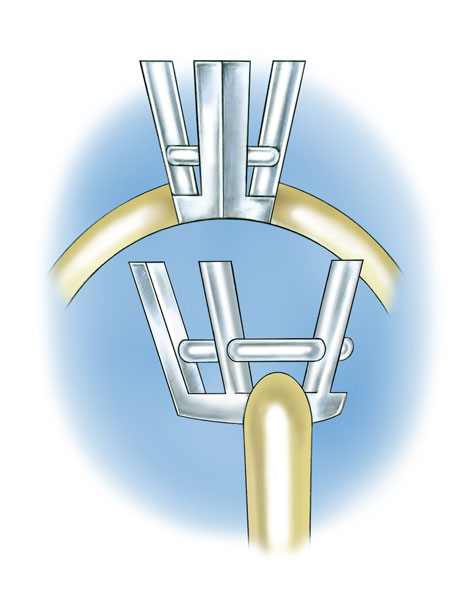

Assembly of a PtCo Pear-Shaped Setting to a 14K Yellow Gold Mounting

play