Sizing Down Platinum Rings

Sizing Up Platinum Rings

Additional Topics

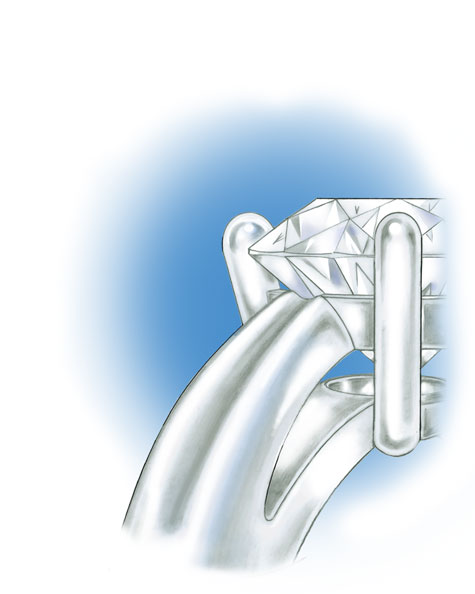

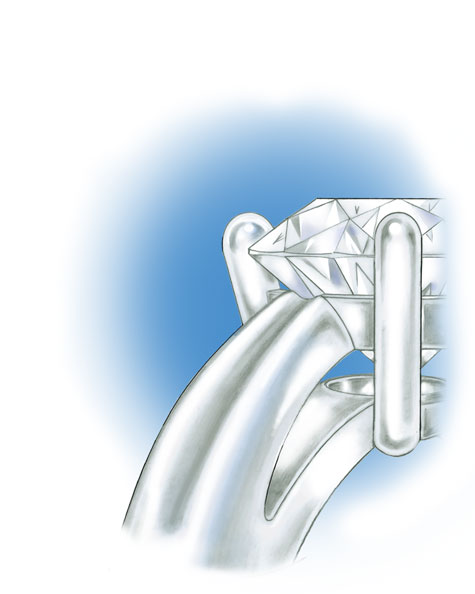

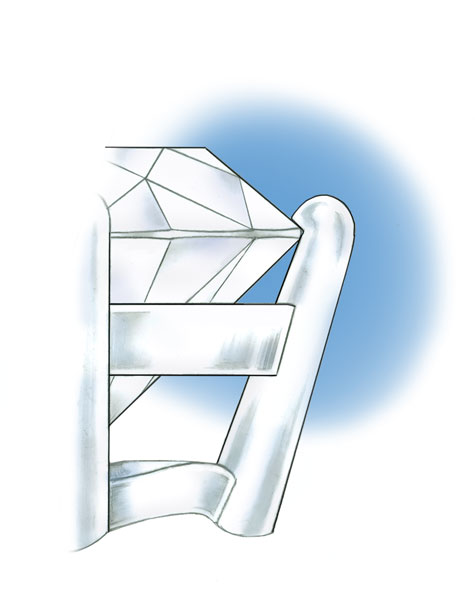

Setting a Round Stone in a Solitaire Ring with Platinum Prongs

play