Sizing Down Platinum Rings

Sizing Up Platinum Rings

Additional Topics

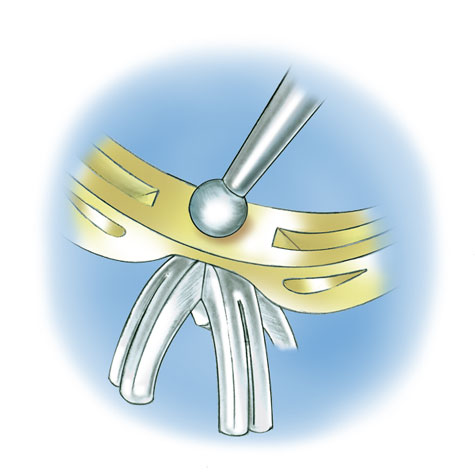

Installing a Round Platinum Ruthenium Peg Setting to a 14K Yellow Gold Mounting

play