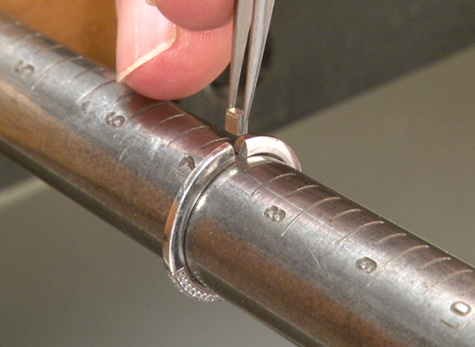

Quality Assurance Benchmarks highlight workmanship of semi-finished and finished jewelry. Learn how to evaluate the quality of a platinum alloy ring with diamonds in the shank that was sized up using a torch.

Potential Problems and Engineering Features

Sizing Stock Alloy Options

How-to Video

Sizing Up a Platinum Alloy Ring with Diamonds in the Shank Using a Torch

playTool and Topic Related Info

After finishing, clean, steam, and inspect.