Best Practices: Platinum Tools and How to Avoid Contamination

Quality Assurance Benchmarks highlight workmanship of semi-finished and finished jewelry. Learn best practices for working with platinum tools, including how to avoid contamination.

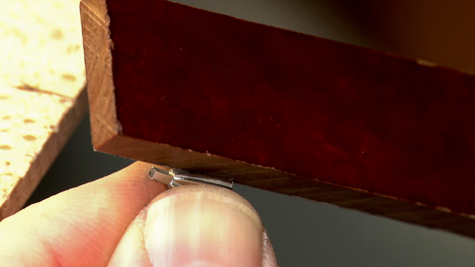

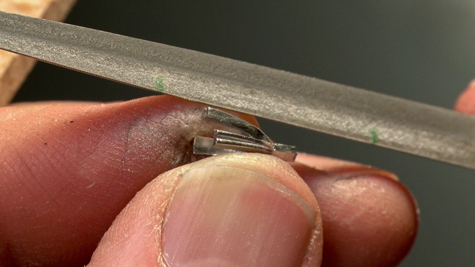

Tools for Working with Platinum

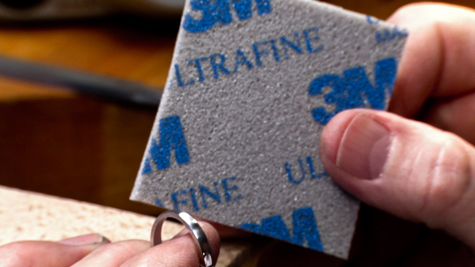

Tools for Prefinishing, Polishing and Buffing Platinum

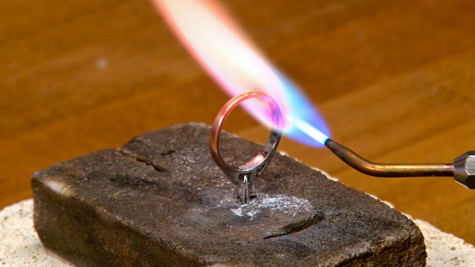

Tools for Soldering Platinum