Considerations for Taking Accurate Measurements of a Finger or Ring

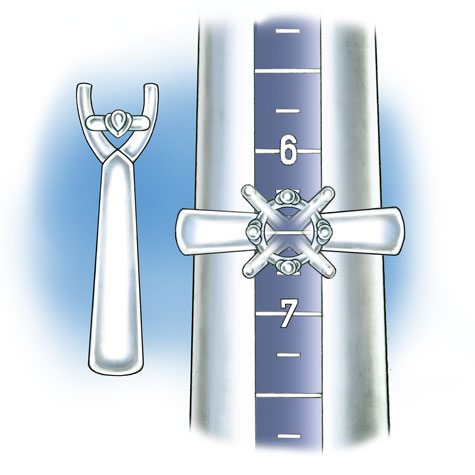

Tools to Determine Finger or Ring-Size Measurements

Tools that are used for accurately measuring finger or ring size

Potential Problems and Engineering Features

Avoiding problems by using the right tools and techniques to measure ring and finger size.

Measuring Finger Size

Techniques to Measure Finger Size

Best Practices for Determining Accurate Ring Sizes

Techniques and Tools to Measure Ring Sizes

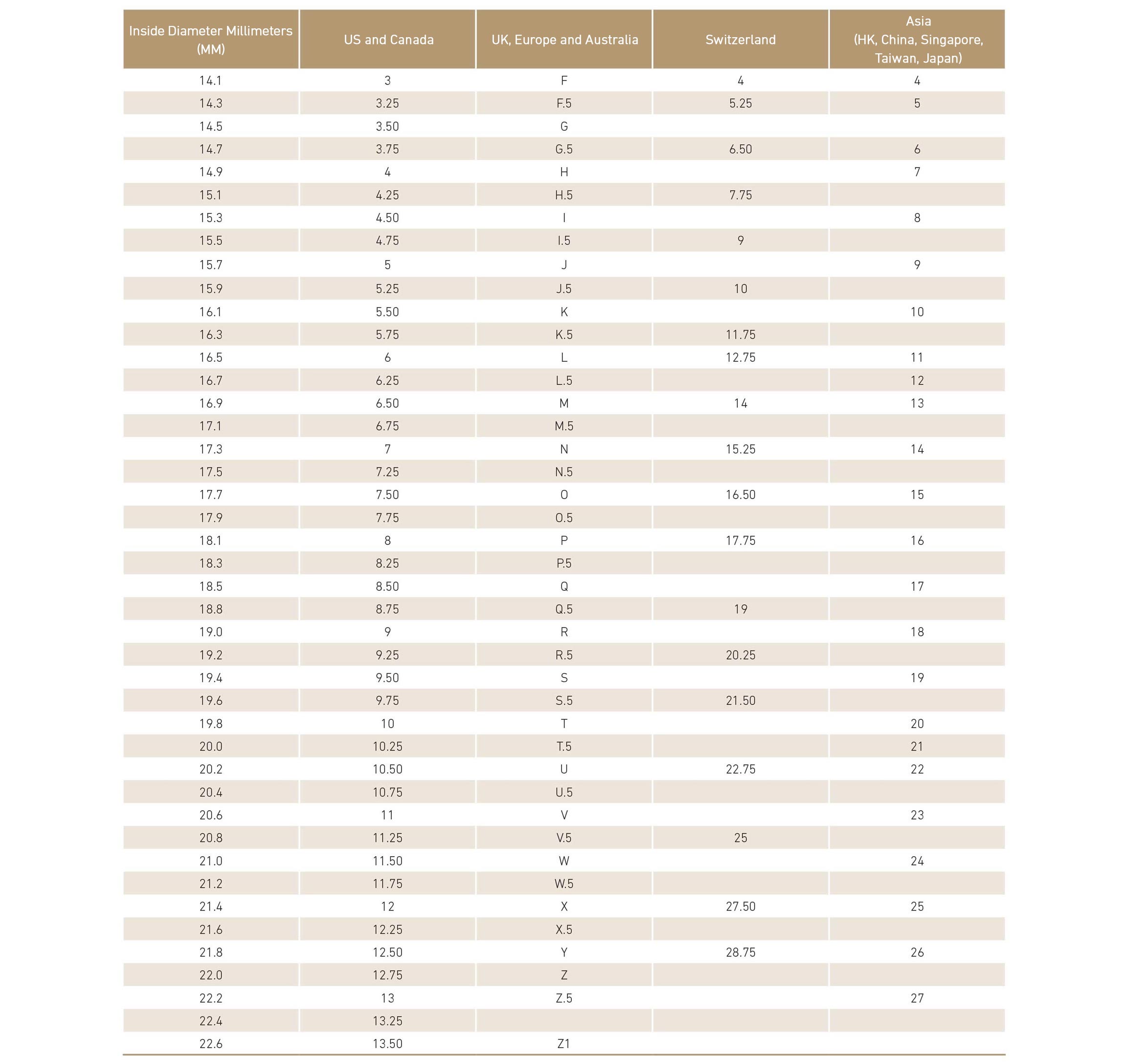

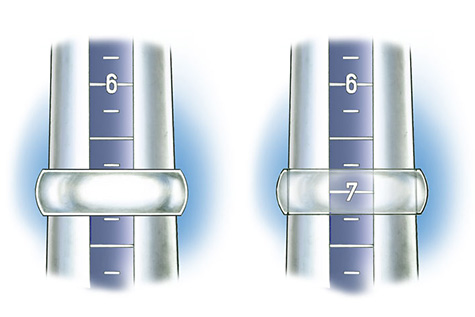

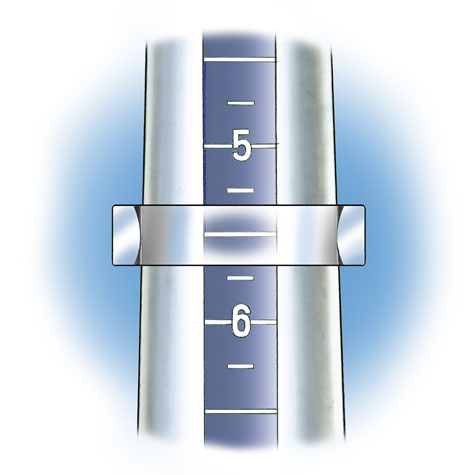

Standard Rings of Even Width

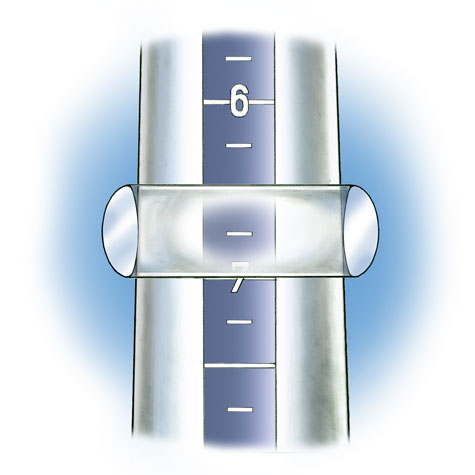

Tapered Rings

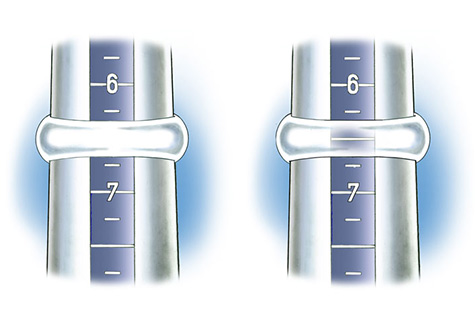

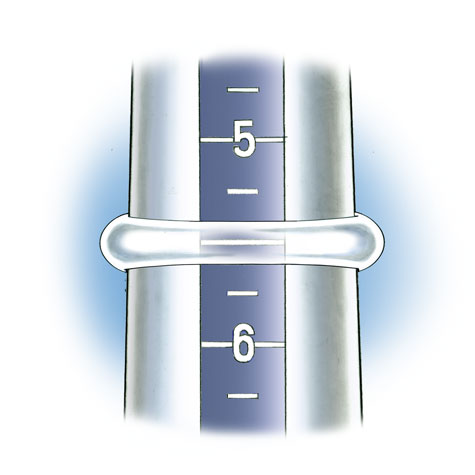

Wide Rings and Bands

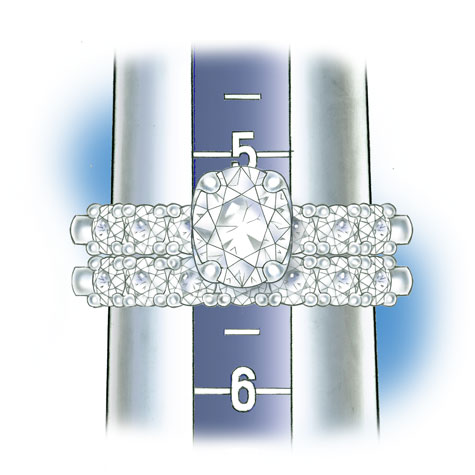

Bridal Sets

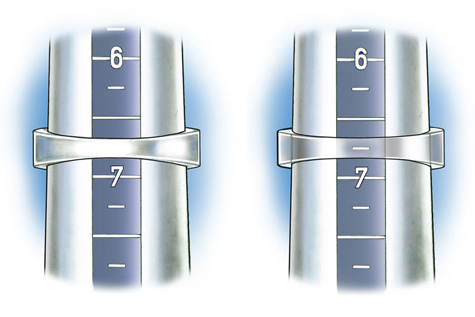

Convex Interior – Rings or Bands

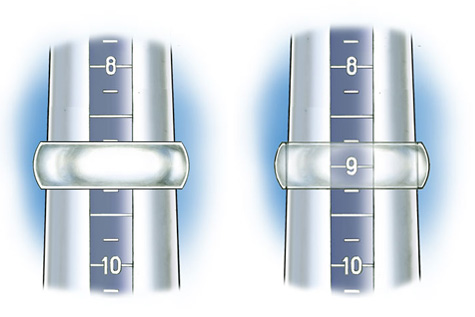

Rings with Open Space Above the Finger

Special Circumstances

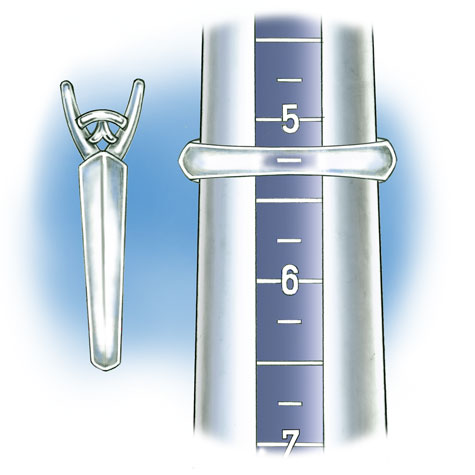

International Ring Size Chart

Another way to measure a ring is to take a measurement of the inside and determine the finger size from a standard chart. The inside of the ring must be perfectly round for this to work.