Sizing Down Platinum Rings

Sizing Up Platinum Rings

Additional Topics

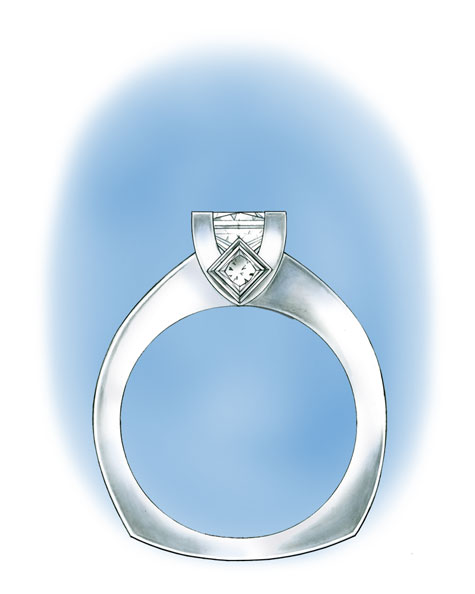

Setting a Princess-cut Center Stone in Platinum V-prongs

play