Panyu: A Legendary Manufacturing Hub for the Global Gem and Jewelry Industry

July 2, 2015

The gem and jewelry industry in Panyu was established in 1986, and now accounts for about 25 percent of Hong Kong’s and mainland China’s combined annual jewelry exports and 60 percent of annual nationwide jewelry production. Panyu workers set more than 70 tons of colored stones into jewelry every year. Panyu’s jewelry exports surged from $2.53 billion in 2011 to $4.13 billion in 2013, with an annual growth rate of almost 28 percent. Seventy percent of jewelry exported from Hong Kong and 90 percent of jewelry branded and sold in Hong Kong is manufactured in Panyu.

In recent years, Hong Kong producers have placed more emphasis on the creative and design side of jewelry manufacturing, leading to higher labor costs. As a result, mass commercial production has mostly moved to Panyu, merging its gem and jewelry industry with Hong Kong’s. Currently, many local and international jewelry brands manufacture their products in Panyu.

Panyu also has more than 1,600 colored stone cutting factories. Panyu gem cutters created the world famous “China Cut” for diamonds and colored stones. It has now become a worldwide brand and the pride of Chinese gem and jewelry manufacturers.

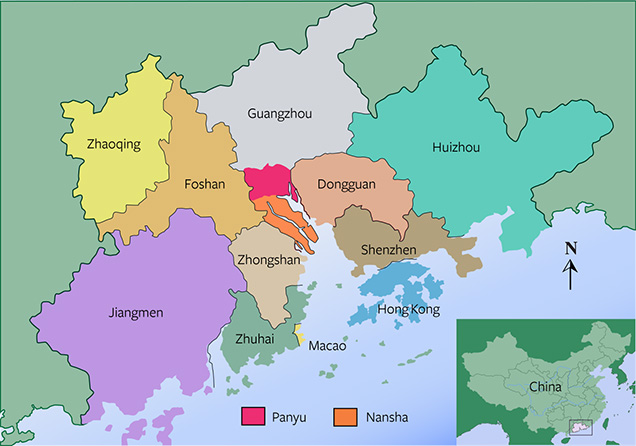

Location Map

Shawan Jewelry Park: A One-Stop Solution

Shawan is a subsidiary district of Panyu. The Shawan Jewelry Park was originally established in 2002 as a gold manufacturing center but its management and strategy changed after 2006. It is now home to jewelry factories, trading offices, an industry service center, and trade organizations. It also hosts tourists and has a large-scale living area for factory employees. In the park, the GIA team visited a well-known jewelry factory and the central business service center.Noble Jewelry Holdings Ltd. is a Hong Kong-based company that was formed in 1983. The company specializes in jewelry design, manufacture, and trading. It was one of the first companies to set its factory in Shawan Jewelry Park. Thirty percent of its products are exported to the Middle East, making the company one of the largest suppliers of high-end jewelry in the area.

Manufacturing Plant

Colored Stone Cutting

Colored stone cutting is another pillar of the Panyu gem and jewelry industry. The team visited the cutting factory of Hutang Gems & Jewelry Ltd., founded in 1992. Mr.Wu Jianping, owner of Hutang, informed us that he started the business in Guangdong and moved to Panyu after a few years. What keeps him in Panyu are the strong government support of the industry, the business services, and the rich human and economic resources.Mr. Wu also proudly expressed to us that the key to his success in the current global industry is that he maintains very strict quality control in his factory, which currently adds more quality control staff than cutters and goldsmiths.

The Greater Panyu Area: Shared benefits and resources

Many of Panyu’s existing resources are shared with its surrounding towns, a few of which have also developed into jewelry manufacturing hubs. Hong Kong’s big three—Chow Tai Fook, Chow Sang Sang, and Luk Fook—have all opened factories in the greater Panyu area.Chow Tai Fook has both its diamond cutting and jewelry manufacturing facilities in Foshan, a city immediately to the west of Panyu. Earlier this year, Chow Sang Sang also opened a center in Foshan to further raise its production capacity in mainland China. The jeweler moved from Guangzhou to Hong Kong in 1948 and had 298 stores on the mainland by the end of 2013.

In 2003, Luk Fook opened its jewelry factory in Nansha District, immediately to the south of Panyu. Luk Fook was founded in Hong Kong in 1991. As the youngest of the big three, its growth in mainland China has been extremely fast. The jeweler operates 1,350 retail stores globally.

All the work—from rough diamond cutting to finished ring—is done in Foshan. Courtesy

Chow Tai Fook.

They use die-striking and electroforming to make some commercial gold jewelry and decorations, while other high-end jewelry is made by hand. All employees are very focused on the details of their work, and commonly use jewelers’ loupes for quality checks. The skill, efficiency, and technology this manufacturer demands are all at the forefront of their operating philosophy.

Transformation and Upgrading

Besides the Pearl River Delta cluster of jewelry industry firms, there are two other clusters in mainland China: the Yangtze River Delta cluster and the Bohai Coastal Region cluster. Clustering offers shared resources, reduced costs, and mass promotion and helps to increase the competitiveness of the local industry.Jewelry Clusters

To address the increasing costs, many factories have invested in more-advanced manufacturing technologies to reduce long-term labor costs, and opened online sales platforms. For example, Shawan Jewelry Industry Park has launched an e-commerce platform that provides services such as warehousing, import and export customs clearance, transportation, and even insurance.

According to the director of the Panyu branch of the China Council for the Promotion of International Trade (CCPIT), the jewelry industry will have to expand further into the domestic market. The Guangzhou Panyu Jewelry Manufacturers Association also works together with business owners to brand the products from all over the Panyu and Pearl River Delta industrial cluster.

The first annual Guangzhou Panyu Jewelry Cultural Festival was held in Panyu at the end of November, 2014. This event will become an annual platform designed specifically for local businesses to display their products and images and to promote jewelry made in Panyu to the rest of the country and the world. Almost all of the participants agree that innovation, technology, and branding will be the key factors keeping the industry advancing in the future.

Dr. Tao Hsu is Technical Editor of Gems & Gemology. Andrew Lucas is Manager of Field Gemology for Content Strategy at GIA in Carlsbad.

The authors want to thank Mr. Wilson Yun, ex-president of the ICA, for introducing us to local industry leaders. We also highly appreciate the assistance from Mr. Cai Yuan Yang, Mr. Kou Liang from Chow Tai Fook, Mrs. Ding Ting from National Gem and Jewelry Testing Center , and Mr. Tony Leung from Shawan Jewelry Industrial Park, who all helped to set up facility visits and interviews in Panyu.

DISCLAIMER

GIA staff often visit mines, manufacturers, retailers and others in the gem and jewelry industry for research purposes and to gain insight into the marketplace. GIA appreciates the access and information provided during these visits. These visits and any resulting articles or publications should not be taken or used as an endorsement.