CVD-Grown Synthetic Diamonds, Part 3: Detection

July 23, 2013

The CVD (chemical vapor deposition) process produces gem-quality synthetic diamond of great beauty, with properties virtually identical to those of natural diamond. Because of their high purity, these CVD products are type IIa—as are only a small percentage of natural diamonds. Therefore, any type IIa diamond should be sent to a well-qualified testing laboratory for identification. Detection has advanced to the point where any CVD-grown sample can be identified with certainty.

The CVD growth process itself occurs under conditions that bring about readily detectable features, including:

1. a low-pressure, highly energetic hydrogen-rich environment

2. the presence of silicon from grower parts

3. the presence of residual nitrogen in the grower

4. the layer-by-layer addition of carbon atoms on the growing surface

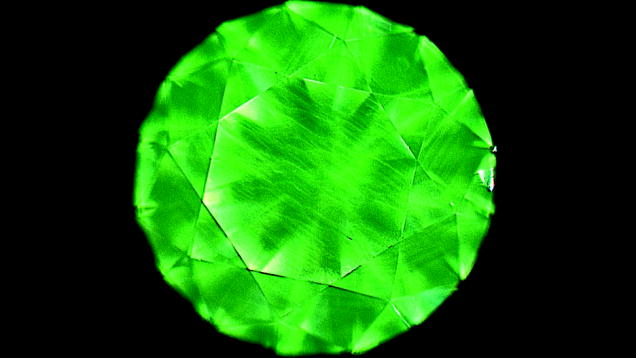

The hydrogen-rich environment leads to defects known as vacancies, in which occasional carbon atoms are missing from their proper location in the diamond crystal. A carbon vacancy residing next to a silicon atom can form a silicon-vacancy (Si-V) center, which is extremely rare in nature. A carbon vacancy next to a nitrogen atom may form a nitrogen-vacancy (N-V) center, which is rarely found in nature. These two vacancy-related defects are detectable through spectroscopic measurements such as photoluminescence, ultraviolet illumination, and optical absorption. In the case of the layer-by-layer growth feature, nitrogen is non-uniformly incorporated into the layers, causing growth striations visible under a DTC DiamondView.

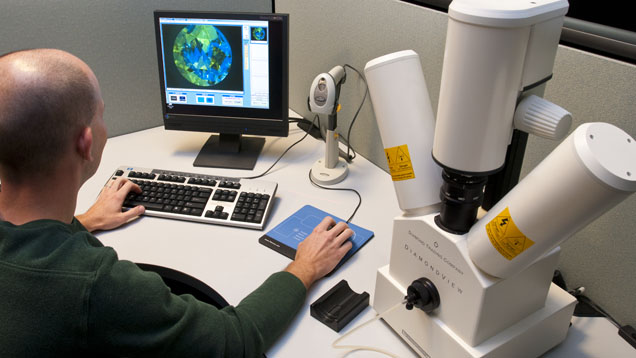

The DiamondView ultraviolet imaging system allows the operator to see a sample's fluorescence patterns from different directions. These patterns are useful in identifying CVD synthesis. Photo by Kevin Schumacher.

Pink-colored CVD synthetics are also readily detected by their abundance of N-V centers. Blue CVDs have been produced by adding boron to the growth chamber, though boron can slow growth so much that only thin films are produced. But even those thin films exhibit CVD-grown features.In summary, CVDs are readily detected in a gem lab, in specimens of any size or color. Detectable features can change under heat treatment (at low or high pressure), but these changes are well understood and can still provide unambiguous detection of CVD-grown synthetic diamonds. For a detailed scientific study and extensive bibliography of detection, see W. Wang et al, “CVD Synthetic Diamonds from Gemesis Corp.,” Summer 2012 Gems & Gemology, pp. 80–97.

About the Author

Dr. Robert Linares is owner of the consulting firm Integrated Diamond Technologies, LLC. An expert in crystal growth technologies, he was co-founder of Apollo Diamond Inc., which produced some of the first gem-quality CVD synthetic diamonds. Dr. Linares received the Department of the Navy’s 2002 Berman Award for breakthroughs in diamond-based quantum computing research and applications.