Expedition to the Cruzeiro Tourmaline Mine in Minas Gerais, Brazil

March 27, 2015

Although the authors had been to many gemstone mines, the size of the mine’s gem-bearing pegmatites and veins and the quantity of tourmaline being produced made this one of the most prolific gemstone mines visited by GIA. You don’t often get a chance to see large, impressive crystals being constantly hauled out of a mine tunnel, with walls and pockets mined with picks and by hand. The tourmaline crystals seemed to be just laying embedded in the enormous pegmatites, waiting to be removed.

History

The history of the Cruzeiro mine is intertwined with the rich mineral composition of the area, tourmalines mistaken for emeralds, mica mined for war efforts, unwavering belief in the richness of the deposit, tragedy, family unity, perseverance, and triumph.An Area Rich in Minerals

As far back as the mid-sixteenth century, the Portuguese were searching for emeralds. They thought they had discovered them in Brazil, but what the so-called bandeirantes had actually found was green tourmaline. During the seventeenth century, a Portuguese explorer documented the gemstones found in the area where the Cruzeiro mine is now located.By the 1800s, the government’s will was strong to discover more of Brazil’s mineral wealth, including gold and precious stone deposits. When explorations in the Minas Gerais area revealed the presence of green tourmalines, explorers again initially thought they were emeralds. This belief led to much interest in further exploration of the area.

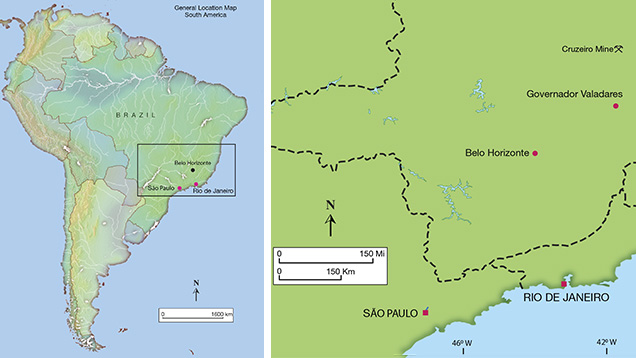

The actual mine deposit in the Cruzeiro area is said to have been discovered in 1915, and the first mining lease was established in 1938. In the 1940s, the US government was greatly interested in exploiting the mica deposits of the area for the war effort. The American company mining the mica employed 800 men, producing an estimated twenty percent of global mica production. The closest significant city, Governador Valadares, experienced significant economic growth during the mica mining period.

Interest in Tourmaline Increases

As the market for mica softened, the brothers started mining and selling tourmalines. At first they were only interested in large, clean tourmaline crystals. As a result, much of the production that was disposed of in waste piles might contain useable material today. The brothers also began cutting and selling tourmalines, as they were interested in moving farther up the value chain.Not long after they became tourmaline dealers, they caught the interest of Julius Sauer of the world-famous Amsterdam Sauer gemstone and jewelry company. Mr. Sauer bought a large portion of the mine’s tourmaline production, then also bought the mine. Mr. Sauer worked the mine for about 15 years during the late 1960s through early 1980s. He then offered it for sale to Jose Neves, who was working for Mr. Sauer, buying tourmaline in the area and in Teofilo Otoni. Jose Neves sold everything he owned and invited his brother Antonio De Assis Neves to partner with him in the mine, which they purchased in 1982.

important product. Photo by Andrew Lucas/GIA, courtesy Cruzeiro mine.

Tragedy, Perseverance, and Success

The family suffered a tremendous tragedy in January 1992, when both Neves brothers died in a plane crash in Brazil. At that time Beatrice Neves, the wife of Antonio De Assis Neves, her son Antonio de Neves Jr., and Douglas Williams Neves, the son of Jose Neves, took over the mine. Douglas was a teenager at the time, but had already spent a considerable amount of time at the mine with his father, where he would mine for tourmaline using a pick. He’d then wash and clean the stones he found and sell them directly to his father.Adding to the event’s tragedy, Douglas’s mother and another aunt also died in the plane crash. Even at that young age, Douglas stepped up and took over running the business with his Aunt Beatrice and her son Antonio. In running the business, Douglas built upon what he learned from his father and followed his own instincts and intuition.

The mining operation today is very successful, with 150 employees. One hundred of them are miners, and the mine has produced an annual average of more than eight tons of tourmaline over the last five years. This was only possible because these resilient family members came together as a team. Along with the loyal employees of the mine, they came through their tragedy and built one of the most successful colored gemstone mining operations in the entire world.

Regional and Local Geology of the Cruzeiro Mine

Cruzeiro is one of the world’s most important sources for gem and mineral specimens. The main mining area is located in the Safira pegmatite district within the Eastern Brazilian pegmatite province (EBPP). EBPP is one of three important pegmatite provinces, mainly situated in the state of Minas Gerais. The southern part of the state of Bahia and the western margin of the state of Rio de Janeiro are also part of EBPP. There are thousands of gem-bearing pegmatites in Minas Gerais, and they contain virtually every known pegmatitic gem mineral species.Neoproterozoic collisions (~1000 to 540 million years ago) led to the final formation of the West Gondwana supercontinent and created the Brazilian orogens of South America and the Pan-African orogens of Africa. Orogens are formations resulting from large-scale continental collisions. Numerous economically important gem deposits have been discovered and mined along these so-called orogenic belts.

In South America, the São Francisco craton (an old and stable part of a continent), which forms eastern Brazil, is surrounded by a sequence of Brazilian orogenic belts. One of them is the Araçuaí belt, featuring west to northwest-extending thrusts and folds. The Araçuaí belt borders the eastern margin of the São Francisco craton and overlaps with EBPP.

During the post-collision stage (530 to 480 million years ago), bodies of intrusive igneous rocks, called plutons, penetrated the metamorphic rocks of the Araçuaí belt. One of these plutonic rocks is considered the source of many pegmatites containing gem tourmaline, spodumene, morganite, and other gems, plus industrial feldspar and muscovite. Although it is quite common to find large batholiths—emplacements of plutonic rock—in the immediate vicinity of gem-bearing pegmatites, in some areas the plutonic source rocks are not well exposed.

quartzite are all sharply defined. The white clay minerals that define the pegmatites are

the products of weathered feldspars, which are more vulnerable to weathering than

quartzite. Below the surface, the width of the pegmatite can be quite different from the

width seen in this partially exposed pegmatite body. Photo by Andy Lucas/GIA, courtesy

Cruzeiro mine.

are indicators that lead miners to gem-quality tourmalines. A good quantity of nice

rubellite crystals was recovered from the pocket in the upper left of this photo. Photo

by Andy Lucas/GIA, courtesy Cruzeiro mine.

The Thrill of Discovery

Speaking with unbridled enthusiasm, Douglas Neves and his Aunt Beatrice described for us the thrill of discovering major tourmaline pockets and crystals. They are ready to come to the mine at a moment’s notice 24 hours a day, and even though they have experienced such moments thousands of times, they feel the same sense of excitement, like a kid receiving his best present, or a parent giving birth to a child. Their first reaction is a desire to keep the tourmaline and never sell it, but the reality is that they must sell their stones to keep the business going. If an important pocket is found, they may work all night to remove the tourmaline crystals, which have become more and more valuable over the last several years, due primarily to the enormous demand in China.

Production

Of the eight tons of annual production, approximately 70 percent is carving and bead quality, 10 percent is clean facet grade, 10 percent is cabochon grade, and 10 percent is suitable for specimens. The Cruzeiro mine produces all tourmaline colors. Douglas estimates that green makes up the largest percentage of total production. Pink and rubellite colors make up about 30 percent, and blue about 10 percent. These color percentages are difficult to estimate because many of the crystals are bicolored or multicolored, with crystals commonly going from pink or rubellite colors to green, and terminating in black. The black tourmaline is often highly fractured and sold for industrial uses.Visiting the Mine

The mine is about 36 miles northwest of Governador Valadares and about six miles from the town of São José da Safira. The latter is named after sapphire, probably due to blue tourmalines found and mistaken for sapphires by early explorers. We drove to the top of the mountain Serra Resplendecente do Cruzeiro, where the mine is located at 4,593 feet. The mine and a small nearby village are both named Cruzeiro, meaning cross due to the presence of a local church.The Cruzeiro mine has an extensive array of horizontal mining tunnels, called galleries, located at different depths. Some of the galleries are very long: One extends to 500 meters. This mine’s pegmatites are enormous. At the deepest mining area, the pegmatite is 32 meters wide and over one kilometer in length. The property itself is close to 3,000 hectares (a hectare is equal to 2.471 acres). The area that is actually being mined is only around 100 hectares, but much of the rest of the property shows promise for successful future production.

ladders, and then following horizontal galleries. Photo by Andrew Lucas/GIA, courtesy

Cruzeiro mine.

GIA team. Photo by Andrew Lucas/GIA, courtesy Cruzeiro mine.

The Mining Operation

In 1996, the mining operation was re-structured to incorporate modern mining methods. Currently, Cruzeiro is working three veins. The current mining plan includes a new entrance and new ramp as well as further assessment of all the pegmatites. They evaluate a pegmatite by looking at its central quartz core zone, where they find green tourmaline at the side contact areas. Next to the green zones are pink and rubellite colors, and then mica. Drilling near the quartz core veins, they look for lines of black tourmaline and indicator minerals of lithium, lepidolite, albite, and mica. Besides tourmaline, they also find colorless, white, and rose quartz, aquamarine, morganite, and red garnets. However, tourmaline is the focus as it’s the most economically important gemstone mined here.

The processing stage is simple and uses classic methods. The rough is washed by hand in wire baskets submerged in large drums of water. Manipulating the baskets in a circular motion allows the water to wash away the smaller pieces of lighter overburden, leaving larger crystals behind. While we watched, several large tourmaline crystals were recovered. Many of them were multicolored, with red-to-pink rubellite transitioning to green, and with black terminations. Some of the crystals were quite large. There were also large blue and green crystals. After washing, the crystals were cleaned further and some were rolled in newspaper for protection, a common technique that’s used especially for specimens.

The Business Model

The mine owners are rejoicing at the current demand for tourmaline in the global market. The mine produces all colors of tourmaline, so they can take advantage of the fact that all colors are in demand. Demand is especially strong for rubellite and bicolor varieties, with strong demand for greens, followed by blues. One of the main tourmaline consuming countries is China. This has been especially true with rubellite and now is also true for bicolors, greens, and blues.

Describing the changes in the price of tourmaline over the last five years, Douglas says, “When I think about the prices I sold tourmaline for five years ago, I did not sell it, I gave it away.” Five years ago it would have been difficult to get $1,000 a kilo for carving and bead-grade rough tourmaline, while today he can easily get $7,000 a kilo. Facet-grade green tourmaline that was selling for ten to twenty dollars a gram five years ago, now sells for $150 a gram.

The Future

When describing the mine’s future, Douglas informed us that they are planning to turn it into a ramp-style mine. The ramp will start at the surface and cut across all five main pegmatite veins currently being mined, plus one more they are planning on mining. Shafts will extend upward from the ramp so they can bring the material down to the ramp and haul it out by truck.With over 95 percent of the property not being mined and large areas showing strong production potential, the future yield of the mine looks strong. Douglas told us that his father always said that his grandchildren would be mining tourmaline at Cruzeiro.

Andrew Lucas is manager of field gemology at GIA in Carlsbad, California. Duncan Pay is editor-in-chief of Gems & Gemology and director of content strategy at GIA in Carlsbad. Tao Hsu is technical editor of Gems & Gemology. Shane McClure is director of West Coast identification at GIA's Carlsbad laboratory. Pedro Padua is the video producer at GIA in Carlsbad.

DISCLAIMER

GIA staff often visit mines, manufacturers, retailers and others in the gem and jewelry industry for research purposes and to gain insight into the marketplace. GIA appreciates the access and information provided during these visits. These visits and any resulting articles or publications should not be taken or used as an endorsement.

The authors would like to thank:

The Cruzeiro Mine

Nevestones

Douglas Williams Neves

Antonio de

Neves Junior

Beatrice Neves

Clement Sabbagh

Miranda Group Co Ltd.