Experimental Studies on the Heat Treatment of Baltic Amber

ABSTRACT

Amber samples were subjected to heat treatment experiments aimed at reproducing heated products found in the jewelry market today. Using a furnace and applying specific conditions, the authors produced four types of heated amber: golden, red, “flower,” and “beeswax.” This paper describes the procedures and parameters that influence the characteristics of heated amber.

INTRODUCTION

Amber’s naturally soft color is appreciated by connoisseurs the world over. In China, the gem has been regarded as sacred since ancient times. It is one of China’s seven Buddhist treasures, along with gold, silver, pearl, coral, Tridacna clams, and liuli (glass). Huge quantities of amber are consumed each year, especially in the Chinese market, but high-quality natural material is rare and expensive. As a result, some dealers seek to improve its appearance and quality through heat treatment, which expands the variety available but poses identification challenges.

Numerous studies have dealt with the identification of heat-treated amber (e.g., Brody et al., 2001; Zhang, 2006; Feist et al., 2007; Abduriyim et al., 2009). Yet the methods of heat treatment are closely guarded and quite complex. Details surrounding enhancement mechanisms, the evolution of flow striations, and the reworking of inclusions, as well as changes in gemological properties under different treatment conditions, are not well understood.

In recent years, a few reports have focused on reproducing the heat treatment of amber (e.g., Zhang 2003; Abduriyim et al., 2009; Ross, 2010). In one study, samples were placed in plant oil or fine-grained sands and heated, improving their transparency and generating “sun spark” inclusions. Such methods are not easily duplicated, however. This investigation adopts standard equipment and procedures for commercial-scale heat treatment and explores the mechanisms behind a series of changes resulting from the treatment.

To simulate the heat-treated varieties available in the Chinese market, the authors chose raw Baltic amber specimens from Kaliningrad, Russia, and performed a series of heating experiments at an anonymous processing facility. We succeeded in producing a full range of heated amber varieties, including golden, red, “flower,” and “beeswax” (figure 1). These experiments yielded useful information about procedures, conditions, and influencing factors for heat treatment. The gemological parameters and inclusion characteristics may provide valuable references for the identification of heat-treated amber.

MATERIALS AND METHODS

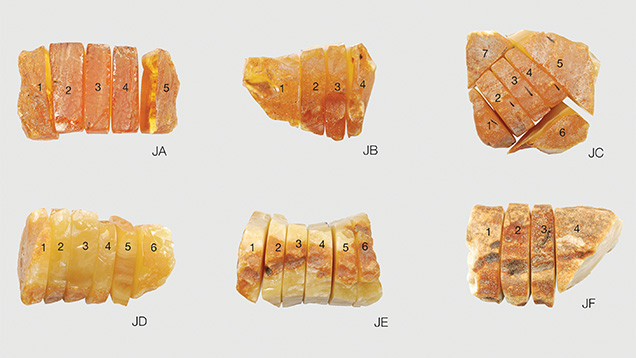

Six good-quality Russian amber specimens were obtained from Beata Amber (Vilnius, Lithuania) for heat treatment. The raw samples weighed 380 g total and were labeled JA–JF. They ranged from orange-yellow to honey yellow in color and from transparent to opaque, with naturally weathered surfaces (table 1). For this study, each specimen was cut into several subsamples, designated as JA-1 through JA-5, etc. (figure 2). This enabled us to track and observe changes in structure and properties at different experimental stages.

For the heat treatment experiments, we used a Kapex AB/3/KAP furnace (figure 3). The automatic control and protection system can be connected to the pressure furnace through a stop valve, depending on the desired enhancement effect. Slowly charging inert gas (N2) into the pressure furnace and heating it removes cloudy bubbles inside the amber, improving its transparency and hardness. By regulating the gas medium used for enhancement, the resulting color can also be adjusted.

RESULTS

The heat treatment of amber generally consists of four stages: preparation, dosing, enhancement, and blowing-out. Details of the stages are described in table 2. Table 3 shows the samples’ appearance before and after treatment, as well as the treatment parameters and overall effectiveness. It should be noted that these parameters are given in averages or approximate values, as detailed data were not divulged by the processing facility.

Tables 1-3 (PDF)

Purification Process. Purification removes bubbles from amber in an inert gas medium, improving transparency. This process requires careful regulation of temperature and pressure inside the autoclave to avoid melting the amber. Thick specimens with poor transparency may need to undergo several rounds of purification, or one lengthy process at higher pressure and temperature. Purification is the primary method for producing golden and pearly beeswax amber, and it is commonly used as a pretreatment before oxidation or sun sparking.

For the first test, we chose samples JA-3, JA-4, JA-5, and JC-7; the JA samples are transparent, naturally golden amber, and JC-7 has an opaque yellow beeswax color. We started with a gas pressure of 4.5 MPa and a room temperature of 27°C, which was increased over a three-hour period to 200°C. That temperature was maintained for about two hours, then cooled down to 35°C over a period of 14 hours, at which point the samples were removed. After purification, all the samples showed better transparency. Sample JC-7 exhibited the most dramatic improvement, changing from near opaque to transparent at the edges, with slight transparency at the center for a pearly beeswax effect. Its color did not change. Samples JA-3, JA-4, and JA-5 changed from golden yellow to brownish yellow. After purification, the JA samples were reserved for oxidation and sparking.

Theoretically, less-transparent amber can be purified in a single round by setting the proper conditions, but since the process is performed in a sealed tank, the effects cannot be observed in real time. To prevent overheating and damaging the amber’s physical-chemical properties, multiple purifications may be used for transparency enhancement. For the second test, semitransparent to opaque sample JB-2 and opaque beeswax samples JB-4, JC-1, JC-4, JD-3, JD-4, JD-5, JD-6, JE-2, JF-1, and JF-2 were selected for two purification cycles, using the procedure described for the first test. The initial pressure was set at 5 and 5.5 MPa, respectively; the temperature was set at 200–210°C, with heating times of five and six hours, respectively.

After two purification cycles, the cloudy inclusions disappeared, turning the samples transparent. Samples JB-2 and JD-3 became transparent brownish yellow golden amber, while the others turned brownish red. Polishing off the superficial red oxidized layers of samples JC-4, JD-4, JE-2, and JF-2 revealed a golden yellow color. After polishing, samples JD-4, JD-5, and JD-6 were set aside for sparking and oxidation. The red oxidation is thought to be related to remnants of air left inside the autoclave from incomplete purging or from the presence of oxygen impurity in the nitrogen gas, either of which would oxidize the amber’s surface and turn it red during purification. Charging air into the autoclave to a pressure of 0.2 MPa and then releasing it would improve air exhaust and help prevent such oxidation. When the preset temperature is reached inside the autoclave, slowly releasing some air and exhaust vapor would help accurately regulate pressure for the purification test.

Oxidation Process. Oxidation at an elevated temperature is the main process used to create red amber. It produces a red to deep reddish brown oxidized layer on the surface. Purified samples JA-4, JA-5, JB-4, JC-2, JD-6, and JF-3 were selected for oxidation in a sealed autoclave. The process was somewhat different from the purification test, in that a small amount of oxygen was charged into the inert gas media, according to a strict volume ratio of the two gases. Too little oxygen would produce an insufficient oxidation effect on the amber surface, while too much oxygen would be dangerous to the test equipment and the material due to carbonization. Pressure was set at 4.5 MPa and the temperature was raised to 210°C over three hours, with inert gas charged into the autoclave together with a small amount of oxygen.

After testing, all the samples had transformed into red to blackish red amber. A longer heating time generally means a deeper color of red amber. If one oxidation did not produce the expected effect, another could be performed. Only gas pressure needs to be increased (under the same temperature) by 0.5–1.0 MPa above the previous oxidation test; otherwise, the amber samples tend to show sparking inside.

“Sun Spark” Inclusions. To create small “sun spark” inclusions, the bubbles present in amber need to be “burst.” After heating the amber as in a purification step, the gas from the autoclave is released, causing a rapid decrease of interior pressure and breaking down the equilibrium between the inner and outer pressure of a bubble. This results in the expansion and sparking of bubbles and the formation of disc-shaped internal cracks, since the pressure inside the bubbles exceeds the pressure outside them. These disc-shaped cracks are termed “sun spark” inclusions. Amber with these inclusions is known as flower amber. Multiple rounds of sparking are needed to produce golden flower and red flower amber varieties.

Conventional sparking consists of deep-frying and baking in sand, and the sparking effect is visually regulated. Because these processes are time-consuming and quantities of amber containing the appropriate amount of gas/liquid inclusions are limited, most flower amber is manufactured by autoclave.

Golden Flower Amber. Sparking for golden flower amber starts with the same procedures used in purification but differs in the latter stages. After heating is complete, the power supply is immediately switched off, releasing gas inside the autoclave to cool down the pressure chamber. Samples JA-3, JD-5, and JE-5, which contain relatively abundant gas bubbles, were selected for this test. To prevent excessive sparking, which would result in cracking, all samples underwent purification treatment beforehand. For the first sparking test, the initial pressure was set at 2.0 MPa. The maximum temperature was set at 200°C, which was reached within two hours and maintained for one hour. Samples that failed to produce a flower effect after the first sparking test underwent a second and in some cases a third sparking test, at successively higher pressure and temperature conditions, until a golden flower effect was obtained. In our testing, sample JE-5 achieved the best results, which came from two rounds of sparking.

Red Flower Amber. Red flower amber is produced by two different methods: (1) sparking red amber and (2) oxidizing golden flower amber. The first process involves manufacturing red amber, stopping the heating, and directly releasing the air. This results in an instantaneous pressure decrease that produces sparking inside the red amber; when the superficial red oxidized layer is polished off, red flower amber is revealed. In the second method, golden flower amber undergoes oxidation treatment and its oxidized skin is polished off. Although the first method is more efficient, both yield identical results.

To produce red flower amber, we chose samples JC-3, JD-4, JE-3, and JE-4. The parameters for the sparking were an initial pressure of 3.0 MPa and a maximum temperature of 200°C after three hours of heating. Sample JC-3 was successful, while the other three failed. Sample JA-5 underwent oxidation, followed by sparking, after which the dark red layer was partially polished off to expose the golden yellow bodycolor. In this manner, golden and red bicolored flower amber was generated.

“Beeswax” Amber. The method for manufacturing “beeswax” amber is relatively simple but consumes considerable time and energy. The process requires prolonged heating and slow oxidation under constant pressure and low temperature. First, samples are arranged in an iron tray that is spread with a layer of fine-grained sand and placed in the furnace. The temperature is set at approximately 50–60°C, for a heating period of 60–100 days. During the baking process, the temperature must be controlled within a certain range. Samples JD-2 and JE-6 were chosen to produce beeswax samples. The specimens were heated at about 60°C for 60 and 90 days, respectively. After heating, the samples had a dull yellow color like ancient beeswax.

DISCUSSION

Heat treatment of amber is aimed at altering or improving color, enhancing transparency, or producing inclusions with special effects. Different results were targeted, including purification, oxidation, “sun spark,” and “beeswax” effects. Based on these tests, several conclusions can be drawn.

Beeswax-colored amber can be purified as transparent golden material using an initial pressure of 4.5–5.0 MPa and a maximum temperature of 200–210°C (reached in three to six hours and maintained for two hours), followed by 14 hours of cooling. Achieving the desired effect, such as pearly beeswax, may require multiple rounds of purification. Purification is also the pretreatment for other enhancement processes.

Well-controlled oxidation generates red amber by producing a red to dark red surface layer. The parameters are an initial pressure of 4.5 MPa (involving a specific volume ratio of inert gas and oxygen) and a maximum temperature of 210°C, to be reached in approximately three hours. The key parameter for oxidation is the amount of oxygen added: Too little oxygen produces a very light color, while too much increases the likelihood of carbonizing the test materials and damaging the equipment.

Samples containing certain levels of gas/liquid inclusions that undergo purification followed by a rapid pressure release acquire internal “sun spark” inclusions, converting them to flower amber. The parameters are: initial pressure of 2.0 MPa and a maximum temperature of 200°C, reached over a period of two hours. Sparking generally requires several rounds of treatment before the effect can be considered satisfactory, with higher pressure and temperature with each additional treatment. Red flower amber can be manufactured by two methods: the sparking of red amber, or the oxidation and polishing of golden flower amber.

Beeswax-colored amber is created by prolonged oxidation (color darkening) on the surface at constant pressure and low temperature, which involves a temperature of about 50–60°C and a baking time of two to three months.

Amber heat treatment is affected by several factors, including:

- Material properties: sample color, transparency, and bulk size, which determine the initial heat treatment parameters.

- Temperature and pressure conditions: the time allowed for heating, maintaining temperature, and cooling, as well as the pressure and the rate of pressure decreases. These are the key parameters for achieving satisfactory amber products.

- Atmospheric inert gas and oxygen, and the ratio between the two, which can determine the color of heat-treated amber.

CONCLUSION

This paper reports on methods of amber heat treatment and discusses several influencing factors. The study suggests that the variety and quality of heated ambers are influenced by the inherent properties (color, transparency, and bulk size) of the natural material, as well as the heat treatment parameters, including temperature, pressure, and atmosphere. Using a furnace and various parameters, four types of heated amber were produced: golden, red, “flower,” and “beeswax.” The study documented the various procedures for amber heat treatment, yielding valuable data on how different effects are achieved.

.jpg)