Lead-Glass-Filled Burmese Rubies

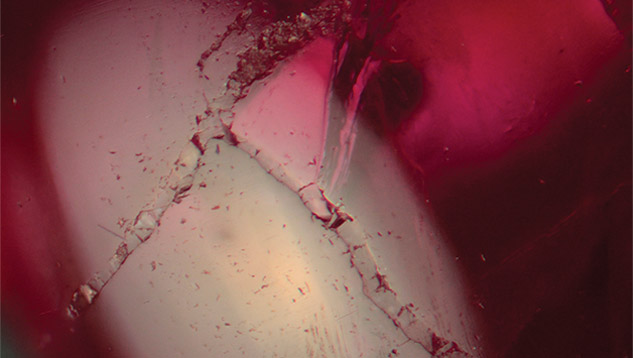

Figure 2. These wide fractures, filled with glass of relatively low lead content, showed a slightly lower luster than the host ruby. Photo by Nathan Renfro; field of view 2.96 mm.

The Carlsbad laboratory recently had the opportunity to examine a multi-strand necklace of graduated round ruby beads (figure 1), measuring 2.72 to 6.13 mm in diameter. Standard gemological testing showed properties consistent with natural ruby. Microscopic observations revealed typical inclusions for ruby: rutile silk, banded particulate clouds, twinning planes, red parallel planar zoning, and roiled graining. The appearance and chemical composition of the beads suggested that their geographic origin was Mogok, Myanmar. Their wide, low-relief fractures (figure 2) and cavities were filled with a foreign substance whose luster was slightly lower than that of the rubies. These observations suggested a lead-glass filler, although the lower luster was contrary to previous documentation and the filler did not display any flash effect. In some beads, the filler also showed a crazed appearance (figure 3) not typically observed in other rubies filled with high-lead glass.

Figure 3. In some beads, the filler also showed a crazed appearance not typically observed in other rubies filled with lead glass. Field of view 2.96 mm.

This strange observation prompted us to carry out a chemical analysis of the glass filler. We tested two spots using laser ablation–inductively coupled plasma–mass spectrometry (LA-ICP-MS) on a relatively large glass-filled cavity. The results after normalization showed that the filler contained approximately 43 wt.% PbO, which was much lower than the lead content reported by McClure et al. in 2006 (71–76 wt.%). The diminished lead content would lower the refractive index of the glass and explain the lack of flash effect and the lower luster observed in this filler.These beads were the first examples of this lower-lead-content glass filling in Burmese rubies examined at the Carlsbad laboratory. On a GIA report, most of these beads would be identified as “rubies with significant clarity enhancement with lead glass filler.” Yet some of the beads were so highly fractured and filled that they would be considered “manufactured products consisting of lead glass and ruby” (figure 4).

Figure 4. Some beads were so highly fractured and filled that they would be called “manufactured products consisting of lead glass and ruby.” This material would easily disintegrate if the lead glass were removed. Photo by Nathan Renfro; field of view 2.96 mm.