Man-made Diamonds: Questions and Answers

September 22, 2017

If it looks like a diamond and sparkles like a diamond, it’s a diamond – right?

These days it’s not so easy to pick out a natural diamond from among the assortment of colorless, shiny stones on display at a jewelry counter. Synthetic diamonds (also known as man-made and lab-grown) and imitation gem materials may also have a spot among the natural diamonds mined around the world. It can be confusing to know what you are looking at and what best fits what you want in a piece of jewelry.

Natural diamonds are one of nature's wonders. They can be several billions of years old, made of a single element (carbon), and are formed deep in the earth under extreme pressure and high temperature. These intense geological conditions produce the physical properties – transparency, optical appearance and hardness – valued in a cut and polished diamond.

“When it comes to a natural diamond, we are looking at something that is really a rarity and a treasure from Earth,” says Brenda Harwick, manager of on campus and lab gemology instruction for GIA. “But man-made diamonds have a place in the market as long as consumers know exactly what it is that they are buying. There are other synthetics out there – such as synthetic ruby, emerald and sapphire – so it’s not something new for the jewelry industry to have a synthetic alternative.”

The jewelry industry uses special terms for manufactured and look-alike materials: synthetic (man-made, lab-grown or lab-created) and imitation (simulants).

Man-made diamonds are grown in a laboratory or factory. Their growth structure and atomic level defects allowing them to be readily separated from natural diamonds by a well-equipped laboratory such as GIA. Because natural diamonds and man-made diamonds have some of the same physical and other properties, even a skilled jeweler or trained gemologist cannot distinguish them by sight alone. It takes specialized equipment and trained staff in a gemological laboratory for a conclusive identification.

Diamond imitations only mimic the look of natural diamonds. Common simulants include colorless sapphire, colorless zircon, synthetic cubic zirconia (zirconium oxide, CZ) and synthetic moissanite (silicon carbide). Cubic zirconia and synthetic moissanite are the most important in the market. They may be natural or made in a lab, but do not share the chemical composition or physical properties of natural or man-made diamonds. Because simulants do not share those properties with diamond, they are more easily distinguished by gemologists.

Man-made diamonds are a more common topic of discussion at the jewelry counter these days because they are being used more frequently in jewelry.

“They may be an option for some jewelry buyers as long as they are correctly identified,” says Dr. James Shigley, a long-time member of GIA’s research team who has studied and published research on man-made diamonds for decades.

It is important that you have some basic information about man-made diamonds and know what questions to ask before you shop.

What are man-made diamonds? Are they real diamonds?

Man-made diamonds have been produced for industrial purposes since the 1950s and are used in a wide variety of applications: telecommunications, laser optics, healthcare and more. In 1970, researchers at General Electric created the first, small, gem-quality synthetic diamonds that could be faceted as gems. By the mid-1980s, other manufacturers were able to grow them. Initially, they were mostly small and yellow, but the quality steadily improved, and today both colorless and colored gem-quality man-made diamonds are available to use in jewelry.

Robert Crowningshield, one of the pioneers of GIA’s research on diamonds and vice president of GIA for many years beginning in 1950, was able to examine some of GE’s man-made diamonds in 1970. He reported on them in a Gems & Gemology article titled “General Electric’s Cuttable Synthetic Diamonds” in 1971.

“Based on his examination of a few of these first experimentally grown synthetic diamonds, it’s amazing to me that he was able to recognize some of the distinctive visual gemological properties of synthetic diamonds – and that those are the same visual features we look at today to identify them,” Shigley says.

The material ‘diamond’ is defined as carbon atoms in a cubic structure; both natural and synthetic diamonds are made of this material.

“The vastly different conditions under which natural diamonds and synthetic diamonds form result in differences in their growth structure and in atomic level defects, so to say that they are identical is misleading,” says Tom Moses, executive vice president and chief laboratory and research officer for GIA. “If they were identical, we would not be able to tell them apart.”

But because they share essentially the same physical and optical characteristics of natural diamonds, man-made diamonds have the shine and sparkle of a natural diamond when fashioned as gems.

“One of the beautiful aspects of a polished diamond is the way light interacts with it, and it has superior hardness on the Mohs scale (which means that polished surfaces are not easily scratched or damaged),” Harwick says. “A synthetic diamond has those properties as well.”

What are they called?

Many different terms are used to describe diamonds grown artificially. Look for the use of the terms synthetic, man-made, laboratory-grown or laboratory-created. These and other terms are listed in the Federal Trade Commission (FTC) guidelines on diamonds.

“The industry uses many terms to describe them, so if you see any of these terms it’s an indication that it is synthetic,” Harwick says. “But they likely won’t use the term synthetic.”

How are they made?

Man-made diamonds are produced in two ways:

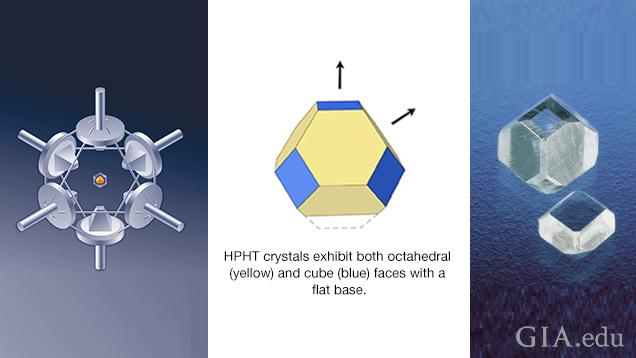

High Pressure, High Temperature (HPHT): A man-made diamond is produced in a laboratory or factory by mimicking the high-pressure, high-temperature conditions that form natural diamonds in the Earth. Within a growth chamber, a source of carbon dissolves in a molten metal, and carbon atoms travel through the metal to a small man-made or natural diamond seed to produce a distinctively shaped man-made diamond crystal.

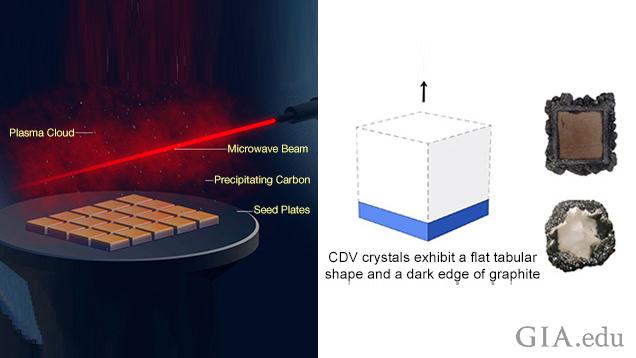

Chemical Vapor Deposition (CVD): A man-made diamond is produced in a laboratory utilizing carbon-rich gas (such as methane) in a vacuum chamber. The CVD process involves breaking down the molecules of methane gas into carbon and hydrogen atoms, which then are deposited on diamond seeds to produce a square-shaped, tabular man-made diamond crystal.

Like natural diamonds, synthetic diamonds can be subjected to treatments to change their color, or to improve their face-up appearance and clarity,” Shigley says.

How long does it take to make a diamond?

It typically takes a few weeks to make a man-made diamond in the laboratory. This is a much shorter period than a natural diamond spends in the Earth, which can be millions or billions of years.

Where are they made?

“We believe that commercial production of synthetic diamonds for jewelry use is taking place in China, Ukraine, Russia, Japan, the United States, and perhaps elsewhere,” Shigley says.

What’s the difference?

Natural diamonds display differences in their properties from man-made diamonds due to the different growth conditions in which they form.

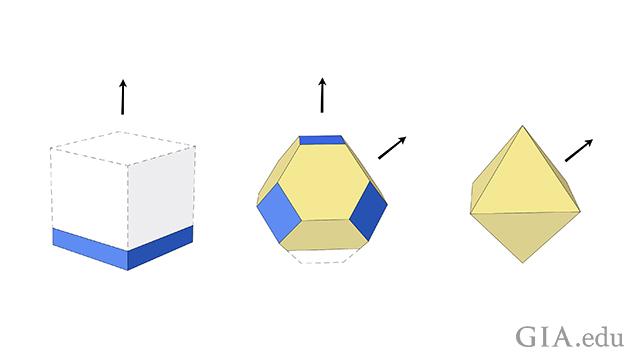

Crystal Shape: The temperatures for natural diamond crystal growth and diamonds made in the laboratory are similar, but diamonds grow as octahedral (eight equilateral triangular faces) crystals and man-made diamonds crystals grow with both octahedral and cubic (six equivalent square faces) crystals.

“Cube faces grow more quickly than octahedral faces," Shigley says. “They are preserved on synthetic diamonds, but they are not preserved on natural diamonds.”

Diamonds grow differently, depending on the growth environment:

- Natural diamonds grow outward on the octahedral faces

- HPHT synthetic diamonds grow outward on the octahedral and cube faces

- CVD synthetic diamonds grow mainly upward in one direction (a cube face)

Inclusions: Natural and man-made diamonds can exhibit various inclusions (fractures, breaks, other crystals, hollow tubes) so they are not always diagnostic tools for gem identification, Shigley says.

Color: Man-made diamonds are commonly colorless, near-colorless, light to dark yellow or yellow-brown; they are less commonly blue, pink red or green. Man-made diamonds can be subjected to the same color treatments as natural diamonds, so any color is possible.

Clarity: Man-made diamonds can be from low to high clarity.

Cut: The cut of a man-made diamond is the same as a natural diamond – any cut is possible. Round brilliant is the most common shape and cutting style of colorless man-made diamonds.

Colored man-made diamonds and larger man-made diamonds are more often fashioned into a fancy shape to retain more weight from the original crystal. The shape of the crystal also influences the choice of faceting styles.

How big are they?

Man-made diamond producers are capable of growing all different sizes, from melee up to 10 carats or more, Harwick says. Typically, most commercial sizes are less than 2 carats, except for melee-size, which can be abundant.

Man-made polished diamonds fall into three size categories, according to Shigley:

- Large size (approximately 5-10 carats or more): These cut stones attract media attention, but they are quite rare and are likely to have been examined and correctly identified by a gem-testing laboratory.

- Commercial size (approximately 0.25 to 2.5 carats): These cut stones are more abundant, but again, they are likely to be submitted to a gemological laboratory for evaluation where they should be recognized.

- Small or melee size (approximately 0.10 carats or smaller): These cut stones are the most abundant, and because of their small size, they will be more difficult to detect and are not often tested – this is the real identification challenge facing the jewelry industry

How does GIA identify and grade man-made diamonds?

Man-made gem diamonds have been extensively studied by gemological researchers for the past 30 years, and much is known today about how they are grown and how they can be identified (there is a lot of published information that has been widely distributed).

“Synthetic diamond identification means distinguishing a natural diamond that formed over a long time, and very long ago, from a synthetic diamond that formed very quickly and very recently,” Shigley says.

GIA has screened every diamond submitted to its laboratory for grading for more than a decade to determine if it is natural or potentially man-made or treated. Following the initial screening, any diamond that is potentially man-made or treated undergoes rigorous examination to confirm if it is natural or man-made, and what treatments – if any – have been applied.

GIA can definitively identify both HPHT and CVD-created man-made diamonds.

What will a GIA grading report tell me?

GIA began to offer a report service for synthetic diamonds in 2006. These Synthetic Diamond Grading Reports, which GIA continues to offer, are distinct from GIA grading reports for natural diamonds in both their appearance and the information provided. They clearly identify that the diamond is man-made or laboratory-grown, and they evaluate color and clarity using descriptive ranges rather than the specific grades of the color and clarity scales.

“When these reports were introduced, there was a range of opinion in the trade about GIA grading synthetic diamonds,” Shigley says. “Since synthetic diamonds continue to be rare, and to differentiate them from what is reported on grading reports for natural diamonds, only color and clarity ranges are used.”

In addition, the man-made diamond’s girdle is laser inscribed with its report number and a statement that the stone is laboratory- grown. GIA does this for every man-made diamond identified in its labs.

“The inscription on the girdle can be key to its identification,” Harwick says.

The reports also use the other Federal Trade Commission (FTC) approved terms – man-made and lab-grown – for synthetic diamonds.

Considering a man-made diamond … what to expect?

Make sure you go to a reputable jewelry store with professionally educated gemologist to purchase any diamond jewelry. They can act as your guide as you look at natural and man-made diamonds.

“A sales associate should articulate or represent and disclose accurately what they are presenting to you. If they are calling it ‘diamond,’ you are assuming it is natural,” Harwick says. “[If it’s not natural] they need to be forthcoming in their description and are required by the FTC to call it laboratory-created, synthetic, laboratory-grown or manufacturer-created.”

Ask the sales associate if it is a natural or man-made diamond and how they know this information.

“Synthetic diamonds may be difficult to recognize by a jeweler or a trained gemologist, but they do not present an identification challenge for GIA,” Shigley says. “There are a variety of instruments being offered to jewelers so they can check for synthetic diamonds, but GIA does not use them so it is not appropriate for us to comment on their operation or accuracy.”

Ask for a diamond grading report from a recognized gemological laboratory – these clearly disclose the identity of the diamond. GIA reports for natural and synthetic diamonds look very different.

“When you’re making an investment in something as precious as this, you should ask for a grading report,” Harwick says.

How much do man-made diamonds cost in relation to their natural counterparts?

Russell Shor, senior industry analyst for GIA, says that producing man-made diamonds, either by HPHT or CVD methods, is quite costly.

“The fact they can be sold for a third or less than a natural diamond suggests they are often priced relative to natural diamonds, rather than priced in a way that reflects a true market for synthetics,” Shor says. Like most technologies, however, he notes that innovations may bring down production costs and, accordingly, the demand for them will increase.

What is the future potential of man-made diamonds?

No one knows for sure if man-made diamonds will become a popular choice for shoppers long-term. There are personal choice issues for each buyer to consider before they purchase one.

“It is up to the preference of the consumer whether they purchase a natural or synthetic diamond, however, proper disclosure about the nature of their stone is paramount,” says Wuyi Wang, director of GIA’s research and development. “As long as the origin of the diamonds is fully disclosed, consumers and the market will determine the future for synthetic diamonds.”

Amanda J. Luke is a senior communications manager at GIA. She is the editor of the GIA Insider and Alum Connect and was the editor of The Loupe magazine.

.jpg)