CVD “Etch” Channel

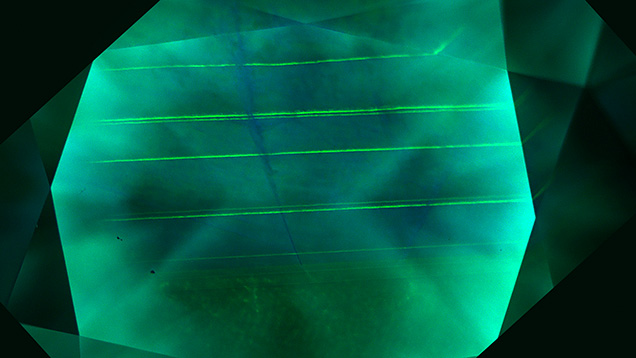

GIA’s New York laboratory recently examined a diamond that had been grown via chemical vapor deposition (CVD) and processed using a high-pressure, high-temperature (HPHT) treatment. Standard grading procedures identified it as a 4.00 ct H-color cushion modified brilliant with SI1 clarity. The diamond was identified as HPHT processed primarily due to the green fluorescence observed in the stone (see figure 3), while distinct fluorescent growth layers across the table and pavilion confirmed its CVD origin.

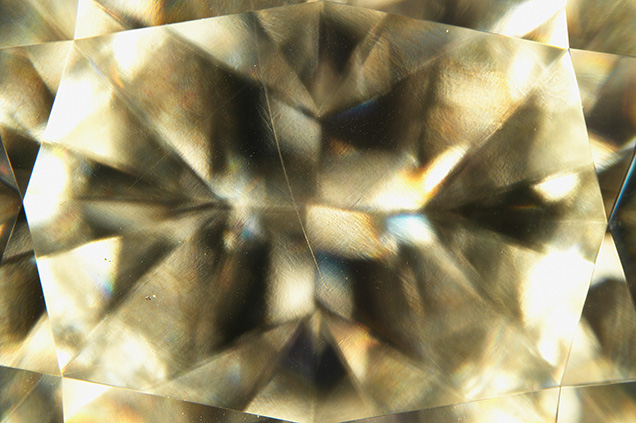

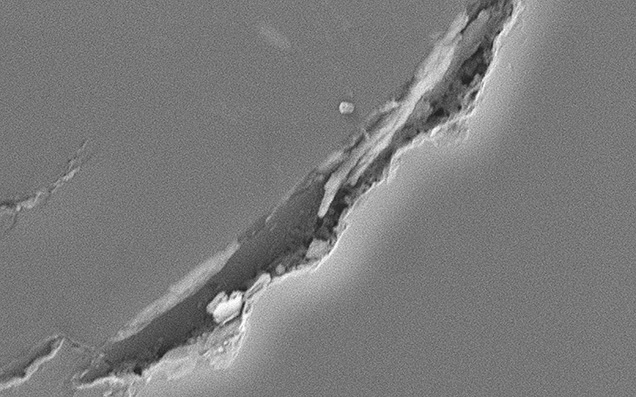

While GIA regularly receives CVD-grown diamonds submitted for laboratory-grown diamond reports, this particular example exhibited a unique characteristic. An etch channel–like structure was plainly visible across the table of the stone, a feature not observed in CVD laboratory-grown diamonds at GIA so far. The channel broke the surface of the table and extended across the stone, ending near a pavilion facet on the other side (figure 1). When viewed under high magnification, a dark residue (figure 2) was observed around parts of the channel. This residue was not present throughout the channel and appeared to be opaque. Close to the surface-reaching channel on the table facet were multiple smaller channels contained within the diamond. The surface-reaching opening of the channel was imaged with a scanning electron microscope (SEM), which revealed a jagged, slit-shaped entrance, suggesting that the shape of the channel extending throughout the diamond structure was similar in nature (figure 4). Some fragmentary material trapped just inside the entrance of the opening appeared to extend into the channel itself. This fragmentary material could have been the same type of opaque residue observed in some areas of the channel.

Fluorescence imaging with the DiamondView instrument also revealed the presence of this channel, which could be discerned by the blue-fluorescing line of dislocation bundles following the channel’s path (figure 3). These dislocation bundles appeared almost perpendicular to the green-fluorescing growth layer boundaries, suggesting the channel was created by exploiting weaker dislocation bundles that propagated through the diamond during CVD growth.

The presence of this channel in a CVD laboratory-grown diamond and the shape of the channel opening were unlike any natural etch channel opening or laser drill hole opening previously seen. It is unclear whether this channel was created during initial CVD growth or during HPHT processing. The opaque residue visible in some parts of the channel as well as the material visible at the channel surface could point to the presence of graphitized carbon, suggesting the channel was a byproduct of HPHT treatment, or it might indicate the presence of non-diamond carbon, which is a common feature found in untreated CVD laboratory-grown diamonds. In summary, the residue may arise from either the CVD growth process or post-growth treatment. Because this feature has not previously been documented at GIA, future studies may help determine the mechanism of action that could create channels in CVD-grown diamonds.