GIA 7 Pearl Value Factors: An Update on Nacre Classification

Pearls, both natural and cultured, form in a wide variety of sizes, shapes, and colors. This diversity created the need to distinguish their various appearances, characteristics, and a host of other complex factors that contribute to determining quality, desirability, and ultimately, value. Researching and studying pearls since the 1930s, GIA developed the GIA 7 Pearl Value Factors classification system, a systematic approach to evaluate a pearl’s various quality factors through consistent methodology and common terminology (J.W.Y. Ho and S.C. Shih, “Pearl classification: The GIA 7 Pearl Value Factors,” Summer 2021 G&G, pp. 135–137). The system, which has been widely adopted in the pearl industry, classifies pearls according to size, shape, color, luster, surface, nacre, and matching.

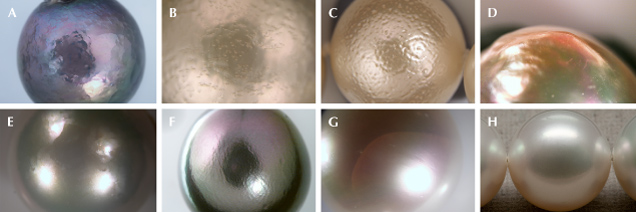

Nacre formation plays a critical role in pearl growth, as its structure influences other value factors such as size, shape, luster, and surface quality. Nacre thickness and continuity also affect a pearl’s durability. Prior to this update, a grade of Acceptable denoted expected commercial quality standards, while Unacceptable indicated poor-quality nacre that may impact durability. Prompted by trade requests and feedback, an expansion of the nacre designation for the GIA 7 Pearl Value Factors classification system recently led to the establishment of a new nacre scale more aligned with other quality factors. To implement this change, a detailed investigation was conducted using a variety of pearl samples with surface and sub-surface features indicating various levels of nacre continuity throughout their growth history. As a result, the new nacre scale contains the following five classification ranges: Excellent, Very Good, Good, Fair, and Poor, based on the evaluation of structural or textural nacre features (sometimes referred to as “movement”) found either on the surface or sub-surface levels of the pearls. Figure 1 shows some examples of these features and an example free of such features for comparison. Most of the photomicrographs shown in figure 1 magnify the surface features for illustration purposes. The actual classification of pearls is performed by visual observation without magnification under suitable lighting conditions. While “hammering” is a widely known and used term in the industry, GIA has internally assigned specific descriptive names and definitions to other movement types for consistency of identification.

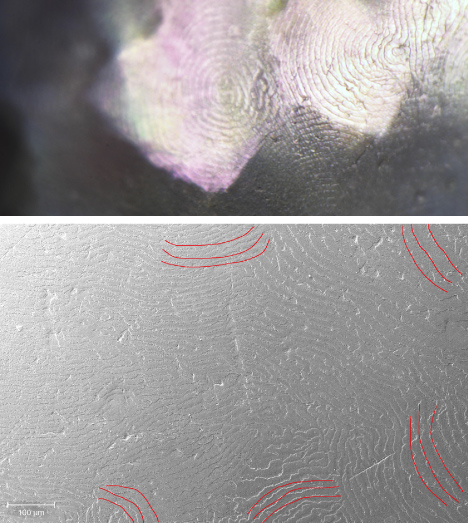

Hammering, named due to its hammered metal appearance (or faceted appearance), exhibits distinct shallow dents or flats that are often seen on baroque pearls but can be present on any shape. This feature can make luster appear softer than it is due to the dispersion of reflections. As a near-surface or sub-surface feature, hammering can often be visible without magnification. Under both conventional microscopic and scanning electron microscopic observations, interesting aragonite nacre platelet structural patterns have been observed in which the nacre on each large planar surface grew concentrically toward its own center (figure 2), as opposed to more integrated and random overlapping nacre platelet structures found on non-hammered pearls. This surface feature is commonly associated with very rapid pearl growth, instead of a growth rate that can provide consistent regular crystal formation for a smooth nacre deposition throughout the whole growth period (J. Taylor and E. Strack, “Pearl production,” in P.C. Southgate and J.S. Lucas, Eds., The Pearl Oyster, Elsevier, 2008, pp. 273–302).

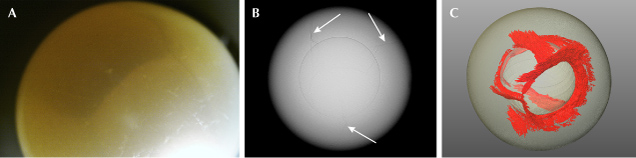

Another feature commonly seen on some pearls is the internal fissures or cracks not far below the nacre surface that can be observed under strong lighting conditions (sometimes referred to as “tidelines”). Figure 3 presents a good example of such a feature: a South Sea bead cultured pearl containing multiple internal cracks beneath the nacre surface. Under X-ray radiographic examination, these internal cracks can extend toward different directions between the bead nucleus and the nacre surface. 3D reconstruction of the X-ray computed microtomography data showed the extent of these cracks radiating from the bead nucleus, providing a better visualization of how these internal fissures are distributed and interconnected with each other (see video). While drilling may occasionally cause internal cracks, undrilled pearls such as this example could also display these growth disruptions within their nacre layers, which may pose durability issues. The exact cause of this feature on undrilled pearls remains unknown.

In summary, the new nacre continuity classification range characterizes the degree of surface or sub-surface nacre disruption, with the baseline being a perfectly smooth, uninterrupted (i.e., Excellent) nacre. Additionally, each cultured pearl type has a minimum parameter for nacre thickness. Based on our observations, most cultured pearls of commercial grade fall into the Good nacre quality range, as opposed to the previous grade of Acceptable, while pearls of higher quality may reach Very Good or Excellent. This update on the nacre quality scale provides improvement to the existing nacre quality description for the GIA 7 Pearl Value Factors classification system.

.jpg)