Mining Diamonds in the Canadian Arctic: The Diavik Mine

ABSTRACT

The Diavik mine, located in the Archean-age Slave geologic province in northern Canada, is one of the world’s preeminent sources of gem diamonds. Since mining operations began in 2003, it has produced over 100 million carats of diamonds. This article will review the discovery, development, and operation of the mine, which is situated in a remote subarctic setting in the Northwest Territories. Four kimberlite pipes occur in close proximity—three are being exploited, while the fourth will be brought into production in 2018. Diavik is now expected to operate through 2024; upon closure, the equipment, buildings, and infrastructure will be removed and the land returned as closely as possible to its original condition.

INTRODUCTION

Canada is the world’s fourth-largest diamond producer, with most of that output coming from one area near Lac de Gras in the Northwest Territories. The discovery of kimberlite pipes there in the early 1990s led to the development of several major mines. Diamond-bearing kimberlite deposits that can be mined economically are noteworthy, since only about 50 such occurrences have been found worldwide since the 1870s, mainly in Australia, Angola, Canada, Russia, and South Africa (Janse, 2007). As of mid-2016, Canada has three active mines: Ekati and Diavik (figure 1), located about 30 km from each other in the Northwest Territories (figure 2), and the Victor mine in northern Ontario. Snap Lake, recently placed in a care and maintenance status, lies within 80 km of Ekati and Diavik. Two other Canadian mines are under development: Gahcho Kué in the Northwest Territories and Renard in Quebec. Figures from the Kimberley Process (www.kimberleyprocess.com/en/canada) show that Canada produced 11.6 million carats of rough diamonds in 2015, valued at US$1.675 billion.

This article will discuss the discovery, development, and operation of Diavik, one of the richest diamond mines in the world. Over several days in late June 2015, the authors visited the site to capture photographs and gather information on the mining operations. The visit involved tours of the open pit and underground workings, the processing and recovery plant, and the facility in Yellowknife where diamonds are cleaned and sorted for distribution (figure 3). In this article, we focus on the unique engineering challenges in developing the Diavik mine and recovering diamonds from beneath a lake in a harsh sub-arctic environment, all while doing so in a way that protects the environment, ensures worker safety, and respects the cultural traditions of the local indigenous peoples.

DIAMOND EXPLORATION IN CANADA

Canada is the world’s second-largest country in terms of land area, but until the 1990s it was not considered an important source of gemstones. During the preceding century, alluvial diamonds were occasionally found in scattered locations across southern Canada and the northeastern United States (Hausel, 1995). Their association with glacial sediments in the Great Lakes region led Hobbs (1899) to propose that the diamonds had been transported by the southward movements of glaciers (which covered large portions of Canada during the Pleistocene epoch, from 2.5 million until about 12,000 years ago) from unknown source rocks in the area near Hudson Bay (see also Bell, 1906).

Kjarsgaard and Levinson (2002) presented a comprehensive review of the discovery and development of Canada’s diamond mines through the 1990s. Although the north-central areas of the country were known to be underlain by ancient rocks of Archean age—the rocks that also host diamondiferous kimberlites in southern Africa and elsewhere—there was little effort on the part of large mining companies to search for diamonds in the Slave craton (Pell, 1995; Carlson et al., 1999). Along with the vast expanse of territory, the very small target area presented by kimberlite pipes, and the cost of search efforts over a period of years, those authors suggested two additional reasons for the lack of diamond exploration programs in northern Canada. The first was logistical: the remoteness of the area, much of it covered by water, and the harsh climate that limited the field season for exploration. The second reason was the glacial dispersal of the contents of exposed kimberlite pipes by the movement of ice sheets away from the original pipe locations. New geological exploration techniques, similar to those being used in Siberia, were needed to search for diamondiferous kimberlites in this type of terrain, which is much different from that of southern Africa (McClenaghan and Kjarsgaard, 2001).

According to Kjarsgaard and Levinson (2002), the modern era of diamond exploration in Canada began in the early 1960s with the traditional search for the diamond “indicator minerals” (such as red Cr-rich pyrope garnet, green Cr-diopside, green olivine, black ilmenite and black Cr-spinel). These minerals, which weather out of kimberlites but are retained as colorful grains in alluvial sediments in far greater abundance than the similarly resistant but much rarer diamonds (Gurney, 1984; McClenaghan, 2005; Shirey and Shigley, 2013). The discovery of these minerals signaled the presence of kimberlites in a particular area, and chemical analysis of them could distinguish those pipes that might contain diamonds. In Canada, the search for these minerals would ultimately involve years of lonely work in a nearly uninhabited and inhospitable region (Krajick, 2001).

The topography of northern Canada has been significantly influenced by periods of glaciation in the geologic past. The land is relatively flat to slightly undulating, marked by low barren hills and shallow bodies of water. In this setting, diamond prospectors had come to believe that sampling glacial eskers (narrow, sinuous ridges composed of sand and gravel sediments deposited by streams from melting glaciers) for indicator minerals might prove successful in locating kimberlites. This had been the case with searching for similar minerals in stream sediments in nonglaciated terrains (McClenaghan et al., 2000; McClenaghan and Kjarsgaard, 2001). Initial target areas included northern Ontario and portions of Quebec, followed by a shift in exploration toward the north and west of the country.

Diamond prospectors who previously found indicator minerals along the Mackenzie River Valley in the Northwest Territories realized that the westward movement of glaciers had transported these minerals from source rocks near the center of the continent. In the early 1980s, improved airborne geophysical survey methods for locating small-target kimberlite pipes over a wide area, combined with a better understanding of how to check sediments from both glacial moraines and eskers, led to preliminary diamond discoveries in various parts of the country. After these initial finds, however, the idea of a more extensive search for diamonds in northern Canada was met with skepticism. Initial exploration efforts involved several major mining companies, but the search was primarily undertaken by smaller companies and even groups of individual prospectors.

In April 1990, after a decade of exploration across an east-west distance of 1,200 km in the Northwest Territories, came Chuck Fipke’s discovery of a bright green Cr-diopside crystal on a ridge at Point Lake, a small, circular crater-like lake just north of Lac de Gras. As this mineral does not survive travel far from its source rock, he concluded that it had come from a kimberlite pipe in the immediate vicinity. This led Fipke and his partner in Dia Met Minerals, fellow geologist Dr. Stewart Blusson, to stake a claim. Years later this area would become part of the Ekati mine (Fipke et al., 1995). Additional heavy mineral samples collected north of Point Lake confirmed the presence of a kimberlite pipe. Partnering with BHP Minerals, a large international mining company based in Australia, they obtained drill core samples from the pipe to better evaluate its mineral content and structure.

In November 1991, BHP announced that 59 kg of kimberlite core samples from the site contained 81 small gem-quality diamonds, and that the company would spend up to $500 million to develop a mine. Over the next 12 months, this stunning development triggered the biggest land rush in Canadian history, as mining companies and individual prospectors staked claims over some 22,000 square kilometers in the north-central part of the country (Krajick, 1994, 2001; Boyd, 2006).

Over the past 25 years, exploration efforts have identified more than 500 kimberlite pipes throughout Canada, with more than 50% containing traces of diamonds. Most of these occurrences are located in the Lac de Gras region near the center of the Slave craton (Carlson et al., 1999). Few of these pipes are directly exposed at the surface; most are buried beneath bodies of water, and they have been revealed by geophysical and field sampling techniques. Because kimberlites weather and decompose faster than much older surrounding rocks, the pipes often occur in topographic depressions beneath lakes. By the end of 1994, a total of 39 kimberlites had been identified in the Lac de Gras area, including what would become the country’s first diamond mine: Ekati, which opened in the fall of 1998. Because these kimberlite pipes were located in an ecologically sensitive portion of northern Canada, the mining ventures had to undergo an extensive environmental, economic, and social review involving several government agencies and local indigenous communities before proceeding with development.

DISCOVERY AND HISTORY OF DIAVIK

By early 1992, Aber Diamond Corporation had staked a claim to 3,250 square kilometers in the Diavik area. The company began a helicopter-borne magnetic survey (in partnership with Kennecott Canada, the exploration arm of Rio Tinto) to identify target locations as prospective kimberlite pipes (Carlson et al., 1999; Graham et al., 1999). A Yellowknife-based exploration company (Covello, Bryan & Associates) was hired for the prospecting activities. Ground, gravity, and other geophysical measurements were also made to confirm that the targets were kimberlites, and to better delineate the size of potential pipes. Samples collected from glacial till, streams, and beaches around these locations were analyzed for indicator minerals. When potential targets were detected, they were ranked in order of priority for additional study based on their geophysical characteristics and proximity to the indicator minerals. Core drilling of the most promising sites was then carried out to determine the lateral extent of the pipe and its micro-diamond content.

Indicator minerals were first discovered on the Diavik property in 1994, near what was then designated as the A21 anomaly, but the decision was made to first core-drill the nearby anomaly that later became the A154 (South) pipe. This drilling produced a section of kimberlite core that broke open to reveal a 2.5 ct diamond crystal (Graham et al., 1999; Tupper and Neamtz, 2002). Considering the rarity of diamonds in kimberlite pipes, to encounter such a large crystal in a random core section was remarkable. In 1995, the adjacent A418 pipe was evaluated for its diamond potential. Drilling revealed that the geomagnetic anomalies were small, steeply inclined, semicircular volcanic pipes that became narrower with depth.

By 1995, four diamond-bearing kimberlite pipes had been located—all beneath the waters of Lac de Gras. The pipes are adjacent to the lake shoreline and lie within 4 km of one another. Additional core drilling was carried out to carefully delineate the sizes and shapes of the pipes, and their potential diamond grade was estimated from analyzing the drill cores. Between 1996 and 1997, the initial pipes—A154 (which was later found to be two adjacent pipes) and A418—were accessed by several large-diameter (approximately 15 cm) holes, core drilling to depths of about 250 meters, and then by underground tunnels excavated 150 meters beneath Lac de Gras. From these activities, 5,937 tonnes of kimberlite ore were recovered from the A154 South and A418 pipes. Evaluation of this bulk sample was critical to determining whether the pipes contained enough high-quality diamonds for mining to be economical. Some of the recovered ore was analyzed at the company’s pilot processing plant in Yellowknife, and the rest was split into two portions for separate evaluation at both the Yellowknife plant and the nearby Ekati mine. In 1998, analysis of 21,013 carats of diamonds (one-third of which were gem quality) recovered from the bulk ore sample provided the first evidence of the mine’s economic potential.

Earlier in 1995, hydrological and geotechnical studies were begun to assist in the conceptual design and development of both the open-pit and planned underground mining operations. These studies have continued to the present day.

Despite the environmental and engineering challenges for large-scale mining in this remote region, Rio Tinto and Dominion Diamond Corp. (formerly Aber) established a formal joint venture in 1999 to develop the property. Rio Tinto managed and operated the mine through a wholly owned subsidiary, Yellowknife-based Diavik Diamond Mines Inc. Diamond production would be divided between the two organizations, with each independently marketing its own share.

In addition to examining the economic feasibility of operating a diamond mine under arctic conditions, the developers conducted environmental risk analysis between 1997 and 2000. A scientific assessment of all aspects of the regional environment provided a baseline to measure the impact of the subsequent construction and operation of the mine. Agreements also needed to be signed with the five First Nations—the Lutsel K’e Dene First Nation, the Yellowknives Dene First Nation, the Tlicho Government, the Kitikmeot Inuit Association, and the North Slave Metis Alliance—which had inhabited the area for centuries. These groups sought the protection of land and lakes and a share of the economic benefits from mining. In 2000, formal permission was granted to the joint venture to begin mine construction. This included an environmental agreement with the Canadian government, and a socioeconomic monitoring agreement with the government of the Northwest Territories.

Between 2000 and 2003, approximately CAD$1.3 billion was spent building the mine infrastructure, one of the largest capital investments undertaken in the history of Canadian mining. This included a plant to process the kimberlite ore and recover the diamonds, office and accommodation buildings for several hundred staff, utilities (electric power and heat generation, water supply, and wastewater treatment), bulk fuel and explosive storage, a maintenance shop, a containment area for storing the processed kimberlite, and an airstrip capable of handling cargo and passenger aircraft. Development of the site occurred in a relatively uninhabited arctic tundra setting—the closest indigenous community was 190 km to the southwest. Everything needed to construct and maintain the site had to be flown in from Yellowknife or trucked over an ice road during wintertime. Transition from a construction project to active diamond production commenced in January 2003, with an expected mine lifetime of about 16–22 years. Sales of the first rough diamonds began in the summer of that year.

In 2006 and 2007, another group of bulk kimberlite samples was collected underground at each of the three pipes (A154, A418, and A21) to determine underground mining conditions, to compare the impact of drill and blast mining versus machine mining on diamond value, and to provide about 15,000 carats from each pipe for additional estimations of rough diamond values. With the exception of the data on diamonds from A21, these 2006–2007 estimates have been superseded by more recent information obtained from actual production parcels from A154 (117,000 and 118,000 carats in May 2013) and A418 (186,000 carats in May 2012). Since 2003, the mine has yielded 100 million carats of rough diamonds, with the largest crystal found to date weighing 187.7 ct (figure 4). Named the “Diavik Foxfire,” it was produced between May 31 and June 6, 2015 (see the Lab Notes section of this issue, pp. 188–189). Previously, the largest gem-quality diamond recovered weighed 151 ct.

GEOLOGICAL SETTING

This kimberlite province, discovered in 1991 and measuring about 400 × 750 km, is a portion of the Slave craton, a region of the continental lithospheric plate (also known as the Canadian Precambrian Shield) that has remained geologically stable since Archean times 2.5 to 4 billion years ago (Pell, 1997; Bleeker, 2002; Davis et al., 2003; Canil, 2008; see boxes A and B and figure 5). In this region, the rocks that compose the ancient crust are exposed at the surface by glaciation. The craton consists of granites and gneisses, with younger volcanic and metasedimentary rocks deposited on them. It sits above a mantle “keel” (a downward-protruding thickened portion of the lithosphere) where relatively low heat-flow and reducing conditions have remained suitable for diamond formation and preservation for an extended period of geologic time (Shirey and Shigley, 2013). Explosive kimberlite magma eruptions rising through this keel zone brought diamonds to the crust. This is a typical setting for kimberlite pipes in Archean cratonic rocks worldwide.

Subsequent to kimberlite pipe emplacement, this portion of Canada was covered by a glacial ice sheet that culminated about 20,000 years ago. As stated above, this glaciation removed much of the topography of the area, including the upper portions of the kimberlite pipes. On East Island, where the Diavik mine is located, the kimberlite pipes are hosted in approximately 2.5-billion-year-old Archean granitic host rocks as well as some younger metasediments. Several Proterozoic diabase dikes cut through zones of structural weakness in these granitic rocks—these same zones may have been where exploding kimberlite magmas broke through to the surface.

Kimberlite pipes are the near-surface conduits of kimberlite volcanoes. As no such eruption has ever been observed, the geological understanding of these events is based almost entirely on observations of the pipes’ complex vertical structure obtained from drill core sections or exposed during underground mining, and from petrographic analysis of rocks found within the pipes (Moss et al., 2008). As in many other kimberlites worldwide, a complete understanding of the magma eruption process is often hindered by subsequent erosion, which removes important upper sections of a pipe.

More than 400 kimberlite pipes are now known in the Lac de Gras area (W. Boyd, pers. comm., 2016). They are distributed along a northwest-trending axis extending more than 120 km. Only a few are economic to mine for diamonds. The Diavik mine lies near the center of the Slave craton. The geology of the four kimberlite pipes on the mine property is now well understood based on field studies conducted over the past two decades (Graham et al., 1999; Bryan and Bonner, 2003). Kimberlites at the mine are interpreted as representing coherent pyroclastic and volcaniclastic types of igneous rocks, and the pipe emplacement has been dated at 55 ± 5 million years ago, during the Eocene epoch (Graham et al., 1999). The pipes are up to 20,000 square meters at the surface, and they extend down to depths of at least 600 meters. Each has a different mixture of kimberlite types and country rock. Field studies of the A154 pipe by Moss et al. (2008) revealed a poorly sorted massive volcaniclastic kimberlite overlain by a better-sorted stratified volcaniclastic kimberlite containing variable proportions of consolidated mud and, at the top of the sequence, a graded pyroclastic kimberlite. The pipes are capped by several meters of glacial till, a thin layer of lacustrine sediments, and 15–20 meters of lake water. Moss et al. (2008) proposed a six-stage explosive eruption model for the A154 pipe:

- Initial kimberlite eruption and excavation of the pipe to form a vertical pipe beneath a surface crater

- Collapse of the pyroclastic gas cloud from above, and partial infilling of the upper portion of the pipe with massive kimberlite from below

- Flows of debris from the surrounding crater walls and further infilling of the pipe, leading to the formation of the stratified kimberlite

- Alteration of rocks within the crater by hot circulating fluids originating from groundwater interacting with the underlying kimberlite magma

- Deposition of sediments in the upper portions of the crater, which now lie beneath a lake

- Deposition of pyroclastic kimberlite in the crater by material ejected from adjacent kimberlite eruptions

At Lac de Gras, glaciation removed the top portions of the pipes. When exposed at the surface, kimberlites weather and decompose, becoming softer than the surrounding country rocks. With the retreat of the glaciers, the pipe locations often became depressions in the land surface, which filled with water to become lakes. The lakes at pipe locations are generally deeper than those formed by just glacial action.

Careful documentation of the different types of kimberlite (and other rocks) within a pipe is important because these factors can exert some control over the size and abundance of the diamonds, and on the processing of the material as kimberlite ore. This typically involves analyzing hundreds of ore samples.

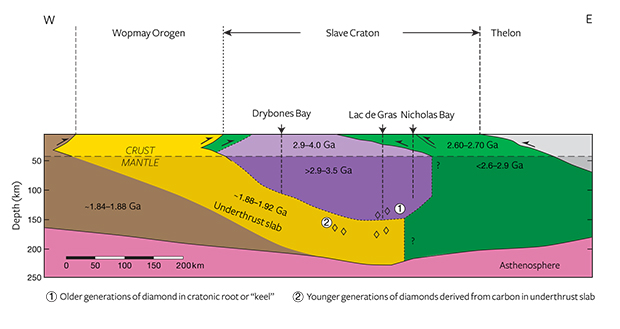

| Box A: The Slave Craton: An Ancient Remnant of Earth’s Early Crust |

| Seismically stable geological areas on Earth are known as cratons. These vestiges of ancient rock are the rarest, smallest, and oldest remnants of continental crust and immediately underlying 150–200 km of mantle (together known as the continental lithosphere). The Diavik mine lies in the middle of the Slave craton, which derives its name from the Great Slave Lake at its southern border. An exciting feature of the Diavik kimberlites, besides their abundance of diamonds, is that the kimberlite punctures and carries deeply derived pieces of the mantle from Earth’s ancient past. The geological history preserved in the Slave craton offers a fascinating record, one that can be read from the complicated surface geology and especially from the deep mantle-derived rock samples brought up within the kimberlite. Like other cratons (e.g., the Superior in Canada, the Kaapvaal in South Africa, or the Pilbara in Australia), the Slave craton is a complicated collage of different continental terranes created at different times and forced together over more than two billion years. The surface geology reveals the different ages of these units, and how they fit together like puzzle pieces. The vertical sampling of diamonds and mantle and crustal rocks by kimberlite that is then erupted to the surface becomes an invaluable tool to peer through the younger crustal rocks, which have a different surface geology from those at 30 to 150 km depths. With enough kimberlites and enough diamonds made available for study from mining operations, a vertical cross section of the craton can even be constructed (figure B-1). At the surface of the Slave craton, the oldest rocks, some ranging in age up to 4.2 billion years, are exposed in the Acasta Gneiss Complex (AGC) on the far west side of the craton and in a north-south belt of gneisses known as the Central Slave Basement Complex (CSBC) in the center. Within these ancient complexes themselves, almost 1.4 billion years of geological evolution can be measured by radiometric dating methods. To the east of the CSBC, the surface rocks are all much younger, more granitic, and clearly related to the modern process of plate tectonic subduction that operated from the craton’s eastern side about 2.5 billion years ago (Bleeker, 2002). Surprisingly, the diamondiferous kimberlites in the Slave craton have erupted through the craton east of the CSBC—coming clearly through parts of the craton that are dominated by younger rocks (most typically 2.5 billion years). Because the diamonds in the Diavik and other kimberlites are much older (up to 3.5 billion years) and similarly old mantle xenoliths occur in the kimberlites, the deep mantle keel must reside some 100 km below younger crust. The surface geology of the Slave craton, therefore, is an asymmetrical geological construct whose depths are known because of diamondiferous kimberlite eruptions. |

LOCATION AND ACCESS

The Diavik mine is located at 64°29ʹ46” N and 110°16’24” W, on a small island in Lac de Gras about 300 km northeast of Yellowknife (the capital of the Northwest Territories), and 220 km south of the Arctic Circle. The mine is situated in a continuous permafrost zone 100 km north of the tree line (the latitude above which trees cannot survive the cold temperatures). The permafrost layer extends from two meters below the surface down to a depth of about 250 meters. The bedrock consists of glacially eroded granite that is covered in many places by glacial till. The till is composed of sand, gravel, cobbles, and boulders in varying proportions in a rock flour matrix. Near the lake shorelines, the finer material has been washed out, leaving mainly boulders. Beneath the lakes, the till is overlain by several meters of fine sediment.

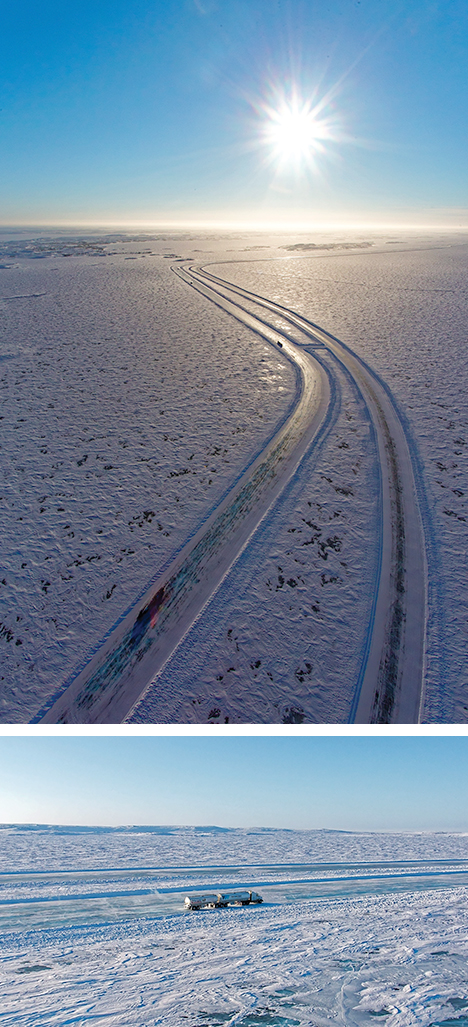

Summers at the site are short and cool, while the winters are long and extremely cold. In winter it is not unusual to have weeks with temperatures between –35°C and –40°C, with frequent strong winds making these temperatures feel even colder. Snow may fall in any month of the year, but it normally occurs between October and April. The region receives only about 300 mm of precipitation per year, mainly in the form of snow, so it can be considered an arctic semidesert. Daylight ranges from about four hours per day in winter to as much as 20 hours per day in summer. Throughout most of the year, the mine can only be reached by air. For a brief time in the winter, an ice road provides vehicle access for thousands of tons of equipment, supplies, and fuel (box C). There is no regular road network in this part of Canada.

MINE DESIGN

The fact that the four kimberlite pipes were located beneath Lac de Gras (figure 6) posed an engineering challenge if the pipes were to be exploited. The option of accessing and mining the pipes underground from an onshore portal tunnel was ultimately rejected because it would require leaving too much valuable kimberlite ore in place for structural support directly beneath the lake bed. Therefore, a traditional open-pit approach was chosen to remove the kimberlite from the upper portions of the pipes. However, this would require the construction of specially designed dikes surrounding the pipes to allow the open-pit mining of ore bodies that would otherwise be underwater. This required dredging of the lake, placing several million tons of crushed rock into the lake to create the dikes themselves, anchoring the dikes to the bedrock, transferring fish from the enclosed areas back into the lake, and removing several million cubic meters of water from the enclosed areas. Particular challenges included building the dikes without direct access to the bedrock beneath the lake, working during winter months of intense cold and extended darkness when the lake surface would be frozen, preventing debris from contaminating the lake, the use of local material for dike construction (blasted and crushed granite taken in stages from the open-pit locations), and a heavy reliance on an indigenous community workforce with no experience in heavy civil construction (Olive et al., 2004).

The retention dikes around the kimberlite pipes prevent water from flowing from Lac de Gras back into the open pits and the underground workings. Figure 7 shows that the dike is constructed with a flexible concrete water barrier that is anchored to the pressure-grouted bedrock. This wall is supported on both sides by a large volume of crushed granite waste rock. Several hundred sensors continually monitor temperature, pressure, and ground movement to ensure the structural integrity of the dikes. The ground that acted as the dike foundation was permanently frozen beneath the land surface but not beneath the lake, so special equipment was needed to maintain the permafrost in those locations. Where the dike crosses an island, special refrigeration systems known as “thermosyphons” were installed to remove heat and allow the permafrost below the lake to remain frozen.

The two initial crushed-rock dikes (surrounding the A154 and A418 pipes) total more than five kilometers in length. They stand as high as 32 meters above the lake bed and are wide enough to allow two large vehicles to pass one another. The dikes were constructed using 4.5 million tonnes of granite waste rock.

Because it is so remote, the mine must operate as a self-contained community. The site covers 10.5 square kilometers and contains a dormitory complex, a dining area, recreational and education facilities, an office and maintenance building, a warehouse, and an enclosed maintenance facility where even the largest hauling trucks used at the mine can be worked on year-round. Emergency response and medical services are also available. A 1,600-meter airstrip on the site can accommodate large transport aircraft throughout the year. All principal mine buildings are heated by a boiler plant and connected by elevated, well-lit enclosed corridors so that workers can pass from building to building without being exposed to the harsh winter climate.

Minimal amounts of water are taken from Lac de Gras. A system has been constructed around the island to collect water for reuse or for cleaning in a treatment plant before it is returned to the lake. A separate plant treats all domestic sewage.

A diesel power plant generates electricity for the entire site. A year’s supply of diesel fuel is stored on-site for the power plant as well as the mining vehicles. Excess heat from the power plant is used to warm some of the buildings and to heat water used in processing the kimberlite ore. In September 2012, a wind farm (figure 8) was added to provide a renewable source of electrical energy via a wind-diesel hybrid power plant. The wind farm, the first of its kind in the Canadian subarctic, lowered carbon emissions from the mining operations and reduced the need for diesel fuel to be hauled in.

A separate plant produces crushed granitic rock for dike construction, maintenance of the airport runway and road surfaces, and for use underground to backfill the open tunnels and other workings once the kimberlite ore is removed. Explosives used in mining operations are stored in a secure facility on-site.

MINING AND PRODUCTION

Operations. Open-pit operations on the two ore bodies of the A154 pipe began in January 2003, and mining of the A418 pipe followed in 2007 (figure 9). This type of mining was economically viable because the tops of the kimberlite pipes were within 20 meters of the surface, minimizing the amount of waste rock that had to be stripped away to expose them (figures 10 and 11). Kimberlite ore and granite rock overburden from the pits are hauled away by vehicles, without a system of ore buckets or conveyor belts. As surface mining is more economical than underground operations, the intent was to remove as much kimberlite ore as possible from the open pits over time. But as the pipe became narrower with depth, a point would be reached where ore could no longer be removed by vehicle haulage, and surface mining would then cease. In 2012, after three years and a cost of CAD$800 million, Diavik completed the transition to underground operations for the three pipes being exploited.

In the fall of 2014, Rio Tinto announced plans to develop the fourth kimberlite pipe on the property. Construction of the dike surrounding the A21 pipe will take four years; it will extend 2.2 km and require 3 million tonnes of crushed granite (figure 12). Production from the A21 pit is scheduled to begin in late 2018. Output from this pipe will not appreciably extend the life of the mine. Rather, it will offset the approaching decline in production from the underground operations and allow a continuation of existing kimberlite ore levels through the processing plant for several years.

Diavik’s original plan called for the eventual development of underground mining operations, primarily by ore trucks driving down a tunnel from the surface (figure 13). Prior to tunneling, an extensive geotechnical survey of the hydrogeology of the ore bodies and surrounding host rocks was carried out. The design of the open pits and the choice of surface mining methods took into account that the pits would be directly above the underground workings. To date, some 20 km of interconnected underground tunnels have been constructed. These heated and ventilated tunnels include rescue bays where miners can retreat for safety in emergencies, vehicle repair shops, ore passes, ventilation systems, water pumping stations, and storage areas (figures 14 and 15). The underground tunnels were designed to prevent rock in the overlying open pits from subsiding. Although surface mining of A154 and A418 has finished, the pits are the secondary access to the current underground workings via two entrance portals. Continuous monitoring of the now-unused open pits ensures the structural integrity of the pit walls, preventing breaching of the dikes from the surrounding lake and flooding of the underground workings.

Two types of underground mining were selected based on safety, cost, and other considerations. A technique known as blast-hole stoping (BHS) was chosen for A154N because of the stronger, more competent kimberlite rock in this pipe. It is a bottom-up bulk-mining method in which several days of ore production can be created with a single explosion. Holes are drilled vertically from a higher stope (mining cavity) and filled with explosives. When blasted, the broken ore falls to a lower stope, where it can be removed by a scoop loader and ore hauler. Once all the broken ore is removed, the open lower stope is completely backfilled with cemented waste rock, and the process is repeated at the higher stope.

A top-down bulk-mining method known as sub-level retreat (SLR) is used in the A418 and A154S pipes, where the kimberlite ore is weaker but contained within a more competent granite host rock. In this method, a series of horizontal tunnels on a single level is excavated into the pipe, and sections of ore above the tunnels are broken up using explosives. The broken ore falls into the tunnel and is removed. Once all the ore on the level is removed, a new set of tunnels is created farther down in the pipe, and the excavation process is repeated. The process creates a large open space within the pipe.

All three pipes are being excavated concurrently, and a mixture of both “hard” and “soft” kimberlite ore is sent through the processing and recovery plants. Although the mine was originally designed to handle 1.5 million tonnes of ore, this capacity was expanded to 2 million tonnes through operational improvements without the need for additional capital investment (Diavik diamond mine: 2014 sustainable development report, 2015). Kimberlite ore and waste rock are brought from the underground workings to the surface by haulage trucks using three portal entrances, and the material is dumped in a designated location on-site. Larger trucks haul the ore to the processing plant, and any waste rock goes to a separate dump location (figures 16 and 17). The decision to use trucks to haul ore and waste rock from underground, as opposed to a conveyor belt or ore bucket system, was based in part on the fact that the loaders and trucks from the open-pit mining operations were already available.

The kimberlite ore is processed in a large building on-site (figure 18) that is estimated to be 11 stories high and approximately 150 meters long and 40 meters wide. The ore first passes through a series of powerful magnets, which remove the unwanted pieces of steel mesh that are used to stabilize the tunnel walls. The ore is then crushed to progressively smaller pieces, removing the finer material. Diamonds are separated from the crushed ore by non-chemical, density-based methods to create a diamond-rich heavy-mineral concentrate (figure 19). Next, X-ray sorting uses fluorescence to recover diamonds from the concentrate. The processed ore material is then stored in a designated area on-site.

Although the diamond grade in the Diavik kimberlite pipes is very high compared to other primary mines, diamonds are still in very low concentrations overall, so a large amount of kimberlite ore must be extracted and processed to recover them. As at other major mines, it is always surprising to hear that most workers have “never seen a diamond in the mine.” Processing of the mixed kimberlite ore brought up from the workings of the A154 and A418 pipes involves a complex series of steps to create progressively smaller sizes to liberate the diamonds from the host rock (figures 20 and 21).

Grease tables are used to retrieve diamonds that cannot be efficiently recovered by X-ray fluorescence technology. Recovery of all diamonds takes place in a restricted area of the plant. Under stringent security, all diamonds are weighed, sorted, and documented before being packaged and flown to Yellowknife. At the product splitting facility, the rough diamonds are cleaned, sorted, and valued for government royalty purposes. The diamonds are separated by size for distribution to the two joint-venture partners, according to the production agreement. Once separated, the diamonds follow different paths for manufacturing and marketing.

Personnel. At the end of 2015, Diavik had approximately 1,000 employees, of whom 55% were from the Northwest Territories and 25% from the indigenous communities. Most employees work on a rotation, with two weeks of 12-hour shifts at the mine, followed by two weeks at home. Managerial staff work four days at the mine followed by three days off-site. Employee transportation to and from Yellowknife is provided by company or chartered aircraft. The mine operates around the clock every day of the year.

Safety. An extensive safety management system governs all aspects of mine operations. The system begins with training of all employees, safety standards for every area of activity, and regular reviews to continually monitor and improve safety practices. Before beginning any work activity, employees conduct a quick safety check to identify and discuss potential hazards associated with the activity, as well as preventive measures that can be taken. The entire mine site is inspected regularly by outside agencies to ensure that all operations are conducted in a manner that protects and enhances worker safety and the environment.

Mine safety is particularly critical when operating in a harsh environment (figure 22). In winter, mining activities can be disrupted by whiteout conditions, where the lack of visibility causes spatial disorientation and can be life-threatening. These conditions occur about four times per year and typically last 8 to 12 hours. Weather monitoring is conducted to warn mine staff of whiteout conditions, as well as the onset of very low temperatures.

Production. With the exception of 2009, when demand was low due to the global financial crisis, annual production of rough diamonds at Diavik has consistently surpassed six million carats. As shown in table 1, Diavik’s total mineral reserves at the end of 2015 were 18.7 million tonnes of unmined kimberlite ore containing an average of 2.8 carats of diamonds per tonne, for a total of 52.8 million carats of diamonds as proven or probable reserves. Table 2 presents annual production data from 2003 to 2014.

| TABLE 1. Proven and probable kimberlite ore reserves at the Diavik mine, as of December 2015. | |||

| Pipe | Tonnes (millions) |

Carats/tonne | Carats (millions) |

| A154N | 8.8 | 2.4 | 20.8 |

| A154S (underground) | 1.5 | 3.3 | 5.1 |

| A418 (underground) | 4.6 | 3.6 | 16.7 |

| A21 (future open pit) | 3.7 | 2.7 | 10.0 |

| Ore stockpile | 0.1 | 3.5 | 0.3 |

| Totals | 18.7 | 2.8 | 52.8 |

|

Adapted from Diavik diamond mine: 2015 sustainable development report (2016).

Tables may not add up due to rounding. |

|||

| TABLE 2. Annual production of kimberlite ore and recovered diamonds from the Diavik mine, 2003–2014. | |||||||||

| Open pit | Underground | Total | |||||||

| Year | Millions of tonnes |

Millions of cts. |

Cts. per tonne |

Millions of tonnes |

Millions of cts. |

Cts. per tonne |

Millions of tonnes |

Millions of cts. |

Cts. per tonne |

| 2003 | 1.193 | 3.833 | 3.2 | — | — | — | 1.193 | 3.833 | 3.2 |

| 2004 | 1.950 | 7.575 | 3.9 | — | — | — | 1.950 | 7.575 | 3.9 |

| 2005 | 2.222 | 8.271 | 3.7 | — | — | — | 2.222 | 8.271 | 3.7 |

| 2006 | 2.331 | 9.829 | 4.2 | — | — | — | 2.331 | 9.829 | 4.2 |

| 2007 | 2.400 | 11.943 | 4.2 | — | — | — | 2.400 | 11.943 | 5.0 |

| 2008 | 2.414 | 9.225 | 3.8 | — | — | — | 2.414 | 9.225 | 3.8 |

| 2009 | 1.359 | 5.565 | 4.1 | — | — | — | 1.359 | 5.565 | 4.1 |

| 2010 | 1.765 | 5.625 | 3.2 | 0.326 | 0.875 | 2.7 | 2.091 | 6.500 | 3.1 |

| 2011 | 1.768 | 5.531 | 3.1 | 0.465 | 1.146 | 2.5 | 2.234 | 6.677 | 3.0 |

| 2012 | 1.116 | 4.006 | 3.6 | 0.942 | 3.224 | 3.4 | 2.058 | 7.230 | 3.5 |

| 2013 | 0.161 | 0.465 | 2.9 | 1.956 | 6.778 | 3.5 | 2.116 | 7.243 | 3.4 |

| 2014 | — | — | — | 2.277 | 7.233 | 3.2 | 2.277 | 7.233 | 3.2 |

| Totals | 18.68 | 71.867 | 3.8 | 5.966 | 19.256 | 3.2 | 24.646 | 91.122 | 3.7 |

|

Source: Yip and Thompson (2015)

|

|||||||||

While the Diavik mine is not known for large diamonds, its kimberlite pipes contain exceptionally high grades (3–5 carats/tonne) of moderate- to high-value diamonds (compared to 0.5 to 1 carats/tonne in other locations). Production from the two operating pipes is valued well above the Kimberley Process average of US$116 per carat—$135 per carat for A154S and $175 per carat for A154N. The average value for A418 is $95 per carat (Dominion Diamonds, 2015).

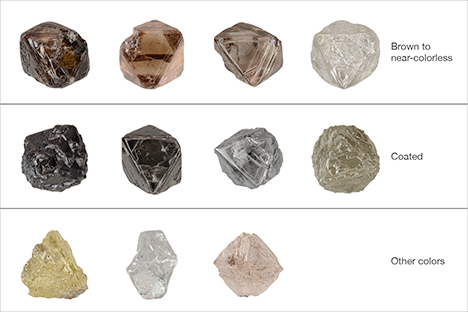

Diamond crystals from the mine exhibit common forms such as octahedra, dodecahedra, macles, cubes, and aggregate shapes. Colorless crystals predominate, though brown and rarely yellow diamonds also occur; some others have a gray surface coating (Carlson et al., 1999).

CORPORATE SOCIAL RESPONSIBILITY

Relationship with Indigenous Communities. The 1991 diamond rush transformed the economy and society of the Northwest Territories. The subsequent development of several major diamond mines in this remote region transpired against the backdrop of a new relationship between the mine owners, the national government, and local communities. Over the past four decades, legislation, land claims, and legal challenges have strengthened the rights of Canada’s indigenous communities over the land and water resources within their traditional territory. An important component of this power-sharing and cross-cultural governance over important land-use, environment, and wildlife decisions has been the increasing reliance on management boards with representation from the federal government, the mining companies, and local communities.

The company maintains a socioeconomic monitoring agreement with the territorial government, as well as environmental protection agreements with the indigenous communities and the federal and territorial governments. Councils involving the indigenous peoples have been consulted on a regular basis about mining operations since the discovery of the diamond occurrence in 1993. Discussions with these local groups have prompted revisions to the mine operation and closure plans, and this is expected to continue as long as the mine is in operation.

A representative body called the Traditional Knowledge Panel advises the company based on centuries of local habitation. For example, traditional understanding of wildlife habitats is being incorporated into the reclamation plan for revegetating the area. There was some discussion in this panel of how far to go in the revegetation process. While some people from the community believed that nature would “heal itself,” most panel members understood that environmental disruptions from mine operations were more extensive than naturally occurring events, and that a more aggressive reclamation process was necessary (Diavik diamond mine reclamation review, 2007; Diavik diamond mine: 2014 sustainable development report, 2015).

As the mine was being developed, agreements were put into place to ensure that benefits would be made available to local indigenous communities. These included job training, employment at the mine, and opportunities for local businesses to provide needed services.

Environmental Monitoring and Protection. At Diavik, all mine activities are designed to protect the environment, anticipate potential problems, and meet regulatory requirements. A surveillance network is in place to monitor the water quality in and around the mine. In addition, the effects of mining operations on local wildlife (including caribou, wolverine, bear, and fish) and habitats (e.g., changes in vegetation) are checked on a regular basis. Efforts are made to minimize the production of dust from roadways and the airstrip.

Mine Closure and Reclamation. From the beginning of mine construction, plans were initiated to return the site to its nearly original condition once mining operations cease in 2024. Progressive reclamation of the site has been ongoing and is expected to cost US$131 million by 2030, once all the works have been removed from the site. A group of indigenous community representatives was organized to provide recommendations for the closure plan. They offered suggestions for revegetation and the creation of corridors for local wildlife such as caribou to pass through the mine site after closure. An important subject has been reclamation of the open pits to restore the original shoreline of Lac de Gras. The processed waste kimberlite ore will be sealed in a special containment area. All buildings and other facilities will be dismantled and removed, with the exception of the wind farm, which may be donated to provide electrical power to the community.

The final steps of the closure plan will be very complex. The waste piles must be shaped to match the natural landscape, which is relatively flat with occasional low hills and granite outcrops. The slopes of the piles must be stabilized to prevent them from giving way and endangering people or wildlife. Finally, the results of the reclamation project must have a neutral effect on the balance of nature in the environment. For example, the restored terrain should make it neither easier nor more difficult for migrating caribou to escape while being hunted by the indigenous peoples. Revegetation must not unduly attract caribou to the area or deter them from migrating through it (Diavik diamond mine reclamation review & cost estimate, 2007).

Even though Diavik was the second diamond mine to open near Lac de Gras, the joint venture faced considerable pressure from the local and federal governments, as well as environmentalists, to ensure the mine closure plan would return the land as closely as possible to its original state. This requirement came in response to the estimated 10,000 mining operations in the Canadian north that had closed with little or no reclamation plan, often posing physical or environmental hazards. For example, the Giant mine, a gold recovery operation near Yellowknife, closed in 1999, leaving 237,000 tonnes of toxic arsenic trioxide stored in the abandoned underground workings. Negotiations are still ongoing to decide on an appropriate clean-up plan and who should pay the cleanup costs (“Giant headache,” 2014).

MARKETING OF DIAVIK DIAMONDS

The rough diamond sorting process is highly automated. After recovery, the diamonds are conveyed into a secured section of the plant where they enter sorting units—large metal canisters containing progressively smaller sieves down to 3 mm. At each sieve level, the diamonds are transferred into separate containers and packaged for shipment.

The Diavik mine is jointly owned by Diavik Diamond Mines Inc. (a wholly owned subsidiary of Rio Tinto plc) and Dominion Diamond Diavik Limited Partnership (a wholly owned subsidiary of Dominion Diamond Corporation). From the mine, the sorted diamonds are flown to a product splitting facility near the Yellowknife airport, where they are divided between the two owners—60% to Rio Tinto and 40% to Dominion Diamonds.

Rio Tinto. This Anglo-Australian mining conglomerate owns a 60% stake in the Diavik mine, which produced 6.7 million carats in fiscal year 2015. It also owns a 100% stake in Australia’s Argyle diamond mine and sells that production in lots separate from Diavik. Rio Tinto markets all of its rough diamonds (figure 23) from a sales office in Antwerp, where it sold 70% of its four million carats from Diavik in 2015 at set prices to 17 “Select Diamantaires” who specialize in manufacturing and distributing Canadian rough and polished diamonds. These clients receive Diavik product via two-year supply contracts (Krawitz, 2015). Like De Beers, Rio Tinto schedules 10 sales, called “core sales,” each year.

Five times per year, Rio Tinto also auctions key assortments from its production to engage with customers outside of its Select Diamantaire base. The company sells fancy-color diamonds and rough diamonds larger than 10.8 ct through two “Specials” tenders each year.

Rio Tinto, under its “Diamonds with a Story” platform, promotes Diavik’s pure and clean Canadian origin and unique provenance. Downstream of the mine, Rio Tinto works in partnership with its Select Diamantaires to provide a tracking system, from the mine to the consumer, for Diavik diamonds (R. Ellison, pers. comm., 2016).

Dominion Diamond Corporation. Dominion Diamonds was originally the Canadian diamond exploration company Aber Resources, which discovered the Diavik site. Dominion owns 40% of the mine; the remainder is held by Rio Tinto, which developed the facility. Aber changed its name to Harry Winston Diamond Company in 2006 after acquiring the venerable jewelry retailer. In 2013, Harry Winston sold its retail division to Swatch, the Swiss-based luxury group, and became Dominion Diamond Company. The same year, the company acquired a majority share in the Ekati mine for $553 million. Dominion markets all of its Ekati and Diavik production separately.

In fiscal year 2015, Dominion sold 3.014 million carats of Diavik’s production for US$351.6 million, averaging about $117 per carat. By the end of 2015, according to Dominion’s annual report, the average per-carat price slipped to $105.

Dominion markets most of its Diavik and Ekati production through its sales offices in Antwerp. About 10% of its production is sold to clients in India ($30.4 million, against total sales of $351.6 million for fiscal year 2015). Initially, the mining companies in northern Canada set aside 10% of their production for local polishing operations (Krawitz, 2014). In 2008 there were six diamond polishing plants in Yellowknife, employing 150 workers (“Diamond cutting and polishing,” 2008). By the following year, however, they all had closed, unable to compete with operations in India and China; this resulted in the loss of CAD$22 million in territorial government investments (Danylchuk, 2011). Attempts to revive a large cutting industry in Yellowknife have not succeeded, and currently there is only one cutting and polishing plant operating (Danylchuk, 2015).

Despite the demise of the local cutting industry, Dominion invested CAD$600,000 in 2015 in branding Diavik and Ekati diamonds by reviving the CanadaMark, a marketing program that was suspended after the local diamond operations closed. The CanadaMark brand is a mine-to-market custody chain designed to give diamond buyers the assurance that their purchases have been ethically sourced in Canada and processed by approved manufacturers. The diamond manufacturers selected to produce the CanadaMark come from the company’s existing customer base in India and Israel, and they are continually audited to ensure sourcing and quality standards. Participating manufacturers offer the CanadaMark diamonds to retail clients who have signed up for the program.

Dominion targets the younger generation through various social media platforms and traditional advertising in print magazines. This age group is very concerned about ethical sourcing, so the chain-of-custody audit is necessary to provide this as well as the assurance that the diamond is truly Canadian.

Dominion hopes CanadaMark diamonds will eventually carry a premium over unbranded diamonds. The company’s focus group research indicates that Canadian consumers will pay as much as 10% more, while buyers in the U.S. and Europe are willing to pay an additional 4% to 5%. Chinese buyers, however, noted they were unwilling to pay any premium based on country of origin (B. Bell and J. Pounds, pers. comms., 2015).

STUDIES OF THE DIAMONDS

Donnelly et al. (2007) presented results from a study of 100 inclusion-bearing Diavik diamonds that had been selected from more than 10,000 carats of “run of mine” production. They found that 83% of the diamonds were derived from peridotitic mantle source rocks, with Mg-chromite and olivine by far the most common mineral inclusions. Van Rythoven and Schulze (2009) examined inclusions and crystal morphology in a group of 110 Diavik diamonds. They also concluded that the majority were peridotitic, and that multiple growth and resorption events had affected diamonds from the A154 South pipe.

To further characterize the production from Diavik, in 2015 GIA acquired over 777 carats from Dominion Diamond. Of these, nearly 500 carats (326 samples) were gem-quality single-crystal diamonds, with the remainder consisting of bort, which was not part of this study. The 326 gem-quality rough diamonds ranged from 1.20 to 1.80 ct, and mainly included D-to-Z range (236), brown (70), yellow (3), gray (16), and pinkish (1) colors (figure 24). Several of the diamonds contained dark-colored inclusions that were assumed to be sulfides and other minerals (figure 25). Since both studies mentioned above were concerned with the inclusions in Diavik diamonds, we decided to focus our characterization on different aspects of the diamonds. Each of the 326 gem-quality diamonds was evaluated for crystal morphology, DiamondView fluorescence, and absorption spectra (FTIR and UV-Vis-NIR).

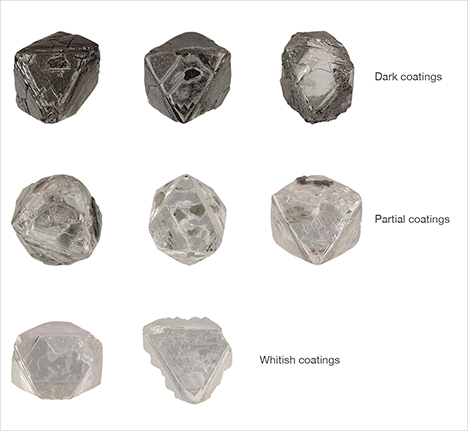

The Diavik rough diamonds examined were dominated by octahedral forms with varying amounts of resorption (figure 26). Of the 326 samples examined, 63% (206 diamonds) showed well-developed octahedral forms with little or no resorption toward the dodecahedral form. Twenty stones were very strongly resorbed to dodecahedral forms. Two showed cube forms, and 14 others appeared to be resorbed cubes that resulted in “hopper” forms. The shapes of 22 diamonds were dominated by twinning, with 17 of those being macles. Irregular forms were observed in 43 diamonds, and an additional 19 samples showed octahedral forms but had a complete or partial coating of light or dark fibrous diamond around a gem-quality interior (figure 27). Many of the rough octahedral diamonds without a coating showed strongly etched crystal surfaces, similar to those seen beneath the fibrous layer on the coated diamonds (where the coating was broken off), suggesting that a much larger proportion of Diavik rough diamonds was coated at one time.

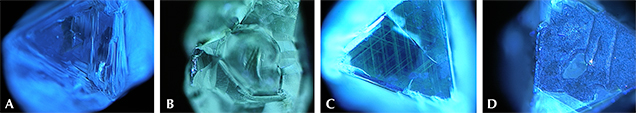

DiamondView imaging revealed uniform blue fluorescence in about 98% of the samples, varying in intensity from very weak to strong (figure 28). Only seven diamonds showed predominantly green fluorescence, all of which had resorbed cube-form “hopper” shapes. Three samples showed isolated patches of green fluorescence from the H3 optical defect oriented along crisscrossing linear planes within the dominant blue. The coated samples showed blue fluorescence in both the gemmy interior and the fibrous coating.

Infrared absorption spectra, collected using a Thermo Nicolet 6700 spectrometer with a diffuse reflectance accessory, revealed that all of the diamonds in this study contained nitrogen impurities and were type Ia. Total nitrogen content ranged from approximately 6 ppm to more than 1000 ppm, with only eight samples containing less than 100 ppm. Nearly 98% of the samples were either pure type IaA (dominated by A-aggregate nitrogen pairs) or mixed IaAB types with various proportions of A- and B-aggregates. Only eight (less than 3%) were pure type IaB (dominated by B-aggregate nitrogen groups), suggesting that the Diavik diamonds had not spent a long enough residence time at elevated temperatures within the earth for advanced nitrogen aggregation to occur (Allen and Evans, 1981).

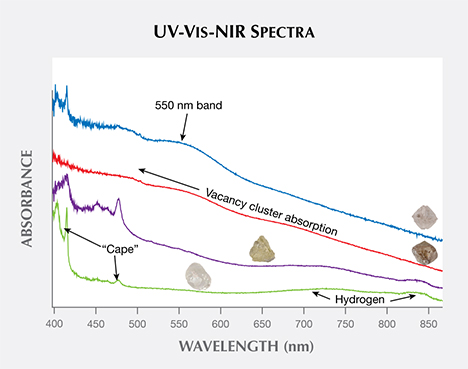

UV-visible absorption spectra were collected at liquid nitrogen temperature using an Ocean Optics CCD spectrometer, integrating sphere, and halogen light source to evaluate the cause of color in the Diavik diamonds. Four UV-Vis spectral features were recorded: “cape” bands at 415 and 478 nm (causing pale yellow color), “vacancy cluster” general absorption increasing to shorter wavelengths (causing brown color), “550 nm” broad band absorption associated with plastic deformation (causes brown or pink color), and broad hydrogen-related bands at approximately 720 and 840 nm (causes brownish or greenish color) (figure 29). Based on the spectra, ~58% of the rough diamonds have yellowish D-to-Z range or brighter yellow colors produced by “cape” bands with or without hydrogen features. With the exception of one pink diamond colored by a 550 nm band and 16 gray stones colored by coatings, the remaining samples were various shades of brown caused by a combination of vacancy cluster and 550 nm band absorptions. The presence of these latter absorption bands in ~37% of the samples suggests that a significant portion of the Diavik diamonds underwent plastic deformation, likely during kimberlite emplacement and eruption.

SUMMARY

Diavik is one of the world’s most modern diamond mining operations. It is the largest diamond mine in Canada, producing approximately seven million carats per year, divided between the two owners. In June 2016, Diavik surpassed 100 million carats of production (“Diavik diamond mine: 2015 sustainable development report,” 2016). Construction and operation of the mine presented considerable challenges because of Diavik’s setting in an extremely remote arctic area that can only be supplied for eight weeks a year via a temporary ice road. The kimberlite pipes are also located under lakes, requiring an elaborate system of dikes and drainage to maintain safe mining operations. While the mine is costly to run safely and sustainably, the high quality of the diamonds it produces (figure 30) will enable it to operate at a profit until its scheduled closing in 2024.