CVD Laboratory-Grown Gem Diamonds from Plasmability

Chemical vapor deposition (CVD) technology has been widely used to grow diamonds for the jewelry market, targeting popular colors and sizes. The majority of these products are colorless to near-colorless, with a smaller proportion being fancy colored. Producers often rely on post-growth treatment for color improvement, with most colorless and near-colorless CVD diamonds having undergone high-pressure, high-temperature (HPHT) annealing (S. Eaton-Magaña et al., “Laboratory-grown diamond: A gemological laboratory perspective,” Journal of Gems & Gemmology, Vol. 23, No. 6, 2021, pp. 25–39). Faceted CVD gem diamond sizes span from melee to tens of carats. It is challenging to grow thick samples without crystal quality degradation. Thus, most sizeable gems are produced through multiple CVD growth stages, resulting in layered growth structures. Close to 10 growth steps have been reported in some CVD diamonds tested at GIA (e.g., Summer 2023 Lab Notes, pp. 213–214). Here we report on colorless and near-colorless CVD gem diamonds from the Texas-based company Plasmability, which were produced by single-step growth up to 9 mm in thickness and were not subjected to post-growth treatment.

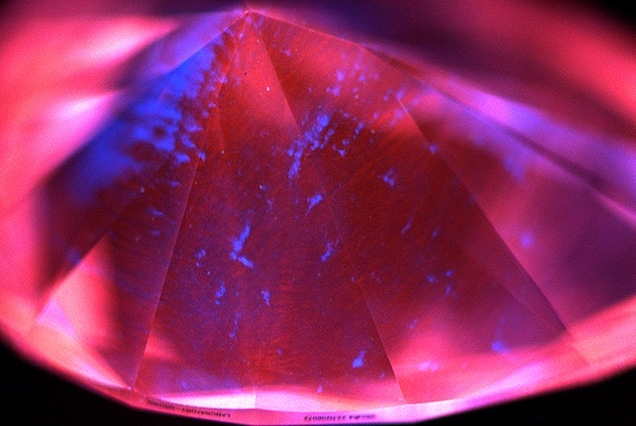

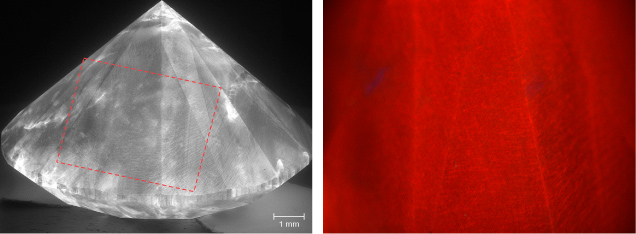

Recently, GIA tested a few thousand laboratory-grown diamonds manufactured by Plasmability. The sizes ranged from about half a carat to more than 10 carats (figure 1). Approximately 85% were colorless, with the rest being near-colorless. Clarity grades varied from VS to VVS. Deep-UV fluorescence imaging is an effective technology for studying diamond growth history, since different growth sectors or growth interruptions will create discontinuities in fluorescence features. Deep-UV fluorescence images collected using the DiamondView were inspected for several hundreds of samples. They were dominated by red–orange emission from NV0 centers, with irregular patches of dislocation bundles, associated with blue band-A fluorescence (figures 2 and 3). No growth layers were observed for tested samples, confirming that they were produced by a single growth step. Excluding the dislocation bundles, the fluorescence was homogeneous, evidence that remarkable control was maintained over the various CVD conditions, including temperature, gas composition, pressure, and power throughout the growth period. Any fluctuations in these parameters would otherwise lead to detectable changes in impurity uptake, typically resulting in interfaces parallel to the growth plane. Complementary cathodoluminescence imaging of a selection of the largest diamonds confirmed these observations (figure 3). A review of gem-quality CVD laboratory-grown diamonds submitted to GIA to date weighing 8.00 ct or more has shown that fewer than 1% were grown without interruption, the largest being a 10.13 ct J-color specimen by Plasmability (figures 1 and 3).

Infrared absorption spectroscopy indicated that these were type IIa, typical for gem-quality CVD-grown diamonds. Most stones showed no absorption features from optical defects; however, very weak absorption at 3123 cm–1 from NVH0 was detected for only a few diamonds. Photoluminescence spectroscopy collected at liquid nitrogen temperature using 514 and 633 nm laser excitations revealed weak emissions at 596/597 nm, in addition to moderately strong emissions from NV0 and NV– centers at 575 and 637 nm, respectively. A weak emission doublet at 736.6 and 736.9 nm due to SiV– was recorded in some samples. These observations strongly suggest that no post-growth treatment was applied and that they were as-grown crystals (U.F.S. D’Haenens-Johansson et al., “Synthesis of diamonds and their identification,” Reviews in Mineralogy and Geochemistry, Vol. 88, 2022, pp. 689–753).

In summary, high-quality CVD-grown gem diamonds are produced by Plasmability using a single-step growth process. Additionally, their colorless and near-colorless grades were achieved without post-growth treatment. This combination of features is rare in gem-quality CVD-grown diamonds.