Bench Tip #5: Repair a Fine Chain with a Soldering Technique

Repairing a fine chain

Chain repair is a set of fundamental skills and techniques every goldsmith needs to master, but the structure and design of the chain dictate what you need to do for a successful repair.This bench trick focuses on fine cable and rope chains with tiny links made from extremely thin wire. It is difficult to manipulate these links, reconnect them and then solder them. Study the chain to determine how each link connects to the next and remove all damaged links, leaving only the sound links that will be joined back together.

Use a permanent marker to color some of the links near the joint so you can find the links that need to be soldered. Cut open one or more links, depending on the style of chain, and open them slightly to connect to the other section of chain. Make sure you fit the cut ends of the link together as tightly as possible to ensure a good solder joint.

The next and most important step is to solder the open links together so they are joined in an inconspicuous way. The chain should look as if it had never been damaged. So easy to say and so hard to do!

You will likely have problems if you apply flux and solder to the open link, then heat it directly with the torch:

• The solder might not flow to both sides of the joint

• A lump of excess solder will adhere to the link because it is impossible to cut solder into small enough pieces for fine gauge links

• Heating the links directly may fuse several links together, which means you must start over on a now shorter chain

This “Sneaky Goldsmith Trick” makes it possible for you to avoid all the pitfalls and do a clean job every time.

The secret weapon is the trusty soldering pick. Normally, goldsmiths use a pick to hold a piece of solder in place or position it on the work. In this case, you will use the tip of the soldering pick to expose the clean metal and apply the flux.

Pick up a piece of easy solder about 1.0 mm square with the pick and heat it directly with the torch until it flows and covers the tip of the pick with a thin layer of solder. Be sure to choose a steel pick, because solder won’t adhere properly to titanium or tungsten.

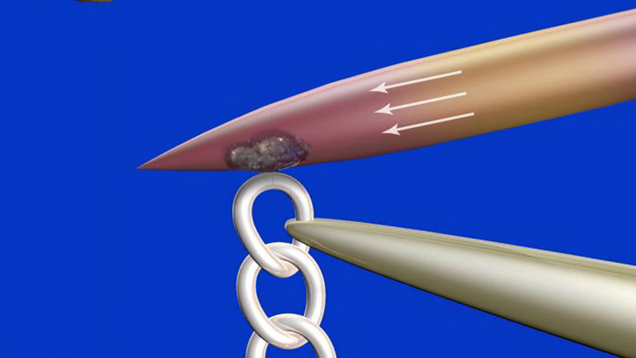

Use a solder pick to transfer heat and a small amount of solder to a small chain link.

Bring the solder-coated pick into contact with the open joint of the link. Instead of pointing the torch directly at the chain, heat the pick about 8 to 10 mm from the tip. The pick will act as a thermal conductor to carry the right amount of heat to the joint to be soldered. When the solder flows again, a small amount of solder will transfer to the joint. Lift the pick quickly. Allow the chain to cool, pickle and clean up as needed.This trick simplifies the soldering process and enables the goldsmith to do better work, faster and with fewer mistakes.