Bench Tip #3: Discover the Benefits of CAD CAM

Discover the benefits of CAD/CAM

CAD/CAM is a term that describes the two-part process of designing three-dimensional objects on a computer (CAD) and manufacturing them with a computerized machine (CAM). For many years this technology has been essential in making products from tennis shoes to automobiles, and it is rapidly gaining importance in the jewelry industry. In fact, many experts believe CAD/CAM will be the primary process of jewelry design and manufacturing in the near future.

CAD is an acronym for computer-aided design, but early on it stood for computer-aided drafting, since it was essentially a tool to make traditional technical drawings with a monitor and a mouse. As technology progressed, it became possible to create three-dimensional “models” within the computer environment. These “virtual solids” can be rotated and manipulated onscreen and examined from any angle, built up and cut away the same as a physical model, and even weighed before they are constructed.

For the bench jeweler, CAD modeling onscreen has more in common with wax carving than with pencil, paper and watercolors. Once the virtual model is completed to the designer’s satisfaction, the CAD file may be sent to a CAM machine for production. Rhino, Matrix, ArtCam, RhinoGold and Solidworks are some of the widely used 3-D modeling software in the jewelry industry today.

The beginning of the modeling process in CAD/CAM. It's easy to add or change elements of a design on the computer.

The advantages of CAD/CAM over traditional manufacturing methods are similar to the advantages of a word processor, such as Microsoft Word, over a typewriter. A typewriter produces “one-off” documents that aren’t easily changeable without starting over. But Word files can be modified easily, copied and pasted into other documents, and saved at each stage for later use.CAD files can also be copied, changed and saved as often as the designer chooses. A model can be designed and saved, then redesigned to create literally endless variations on a theme. A file can be called up the next day or 10 years later and still be redesigned and sent to the CAM machine. Some manufacturers have stopped making master models since they only need to open the original CAD file and send it to the CAM machine to produce an exact duplicate of the master. Many smaller jewelers own just the CAD software and simply e-mail their CAD files to CAM service bureaus, which fabricate the models for them.

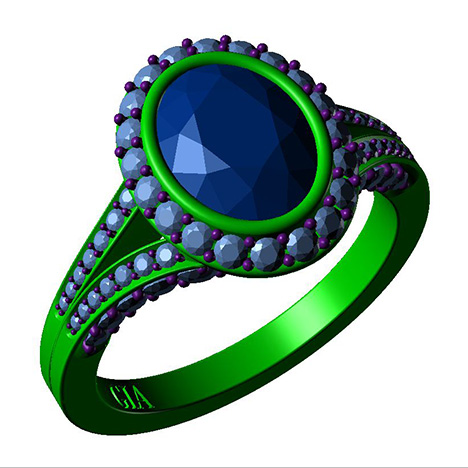

The final design in CAD/CAM.

Besides its advantages in the manufacturing process, CAD software can work in tandem with high-tech rendering software such as V-Ray, Brazil and Maxwell to produce spectacular photorealistic images of virtual jewelry models before the actual piece is made. These images can be extremely effective marketing and sales tools.

A rendering of the design created in CAD/CAM.

.jpg)