CVD-Grown Synthetic Diamonds, Part 1: History

April 30, 2013

In 1954, two years before the announcement of HPHT synthesis, a patent was issued for another type of diamond growth: the CVD (chemical vapor deposition) process. Early reports of gem-quality CVD synthetic diamond were greeted with skepticism and not verified until many years later. In the late 1980s, scientists with a highly advanced understanding of the technique discovered how to reproducibly grow diamond using the CVD process.

The CVD process is quite different from natural diamond formation. It produces diamond from a heated mixture of a hydrocarbon gas (typically methane) and hydrogen in a vacuum chamber at very low pressures. Under normal circumstances, heating this mixture at such low pressures would produce graphite or some other non-diamond form of carbon. But in a CVD growth chamber, some of the hydrogen is converted to atomic hydrogen, which promotes diamond formation since diamond is more stable in this environment. The conversion of molecular hydrogen to atomic hydrogen is accomplished through methods such as the application of microwave energy, an electric discharge, or hot filaments. When atomic hydrogen is present in the gas phase, two chemical processes occur:

(1) Graphite and other non-diamond carbon react with the atomic hydrogen and evaporate in a newly formed gas phase.

(2) Atomic hydrogen reacts with the original hydrocarbon gas (methane) to form a highly reactive carbon-hydrogen species. When this species decomposes, it gives up its hydrogen to form pure carbon: diamond.

To produce a gem-quality synthetic diamond, a diamond seed crystal (natural, HPHT, or CVD in origin) is introduced into the gas mixture, at an elevated temperature of 900 to 1200°C. The activated carbon-hydrogen species travels across the surface of the diamond seed until it finds an available carbon atom, and then attaches itself to this seed atom. The seeded growth is now one carbon atom thicker. This process repeats itself endlessly to replicate the crystal structure of the diamond seed crystal in three dimensions.

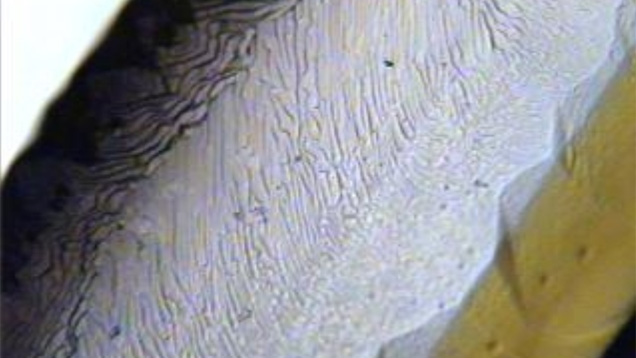

Figure 1. This photo shows the growth of colorless diamond, approximately 1 mm thick, on a yellow HPHT-grown diamond seed.

Figure 1 shows the growth of colorless diamond on a yellow HPHT-grown diamond seed. This particular crystal is approximately 1 mm thick. Thicker crystals can be produced by extending the growth time, either by leaving the crystal in the growth chamber or by removing the seed, inspecting it, and returning it to the chamber for additional growth. To date, diamond crystals 3 to 5 mm thick have been grown and fabricated into gemstones. One of the subtleties of seeded CVD growth is that even though it can produce thick growth vertically, lateral growth is limited by quality considerations. Thus the seed diameter must be at least as large as the desired diameter of the final gemstone. Each new gem growth requires a seed crystal, so either the seed must be reclaimed and reused, or growth capacity must be set aside to continuously manufacture seeds.The earliest CVD growth chambers enabled growth on only one seed at a time. Although reactor seed capacity is a closely guarded industrial secret, some CVD manufacturing systems are reportedly capable of growing on 50 or more seeds simultaneously. That number is expected to increase in the future.

Figure 2. CVD-grown cut and polished synthetic diamonds.

CVD synthetics are cut and polished in the same manner as natural diamonds, at the same cost. The stones can be laser inscribed on the girdle to allow easy preliminary identification. Figure 2 shows typical CVD-grown cut and polished synthetic diamonds.In the next installment of this series, we will look at the properties of CVD synthetic diamonds.

About the Author

Dr. Robert Linares is owner of the consulting firm Integrated Diamond Technologies, LLC. An expert in crystal growth technologies, he was co-founder of Apollo Diamond Inc., which produced some of the first gem-quality CVD synthetic diamonds. Dr. Linares received the Department of the Navy’s 2002 Berman Award for breakthroughs in diamond-based quantum computing research and applications.