Bench Tip #18: How To Modify a Wooden Ring Clamp

Modify a Wooden Ring Clamp

One persistent daily challenge a bench jeweler faces is trying to figure out the best way to hold onto tiny, delicate objects while performing mechanical operations such as sawing, filing or burring bearings for stone setting.There are dozens of tools available for this purpose, some centuries old and some that are modern, sophisticated and often quite expensive. An alternative is to make a simple modification to a wooden ring clamp—which holds rings and other jewelry items—that turns it into a useful, multi-function holder.

The ring clamp is usually braced against the bench pin as you work. Trouble can develop if the clamp slips while you are applying pressure. When you push downward on the ring with a prong pusher, for example, the clamp can slip out of place—even slightly—and cause a sudden movement that results in a chipped stone, damaged prong or injury to your finger or hand.

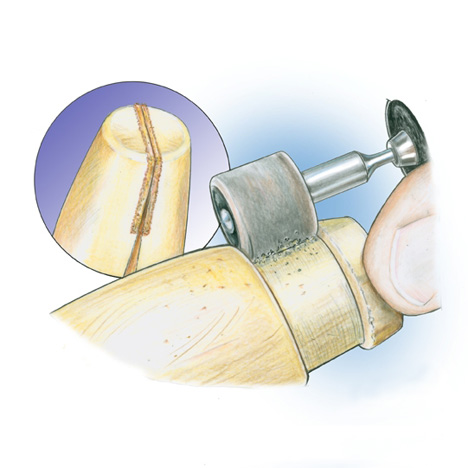

The inset shows the original shape of the ring clamp. Grinding a groove to modify it will help brace the clamp more securely and give you a greater range of motion as you work.

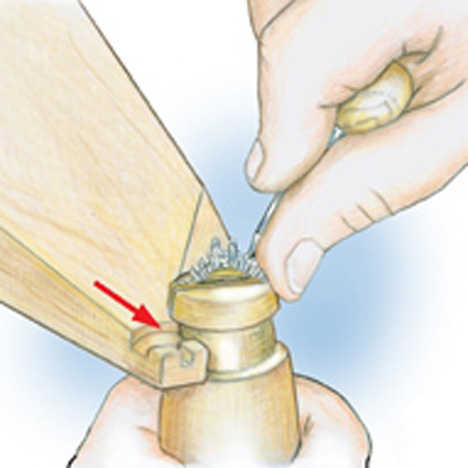

If you grind a channel in the ring clamp, however, you can lock it in place with the bench pin. This provides more stable support for the work in progress and enhances your accuracy and safety.

The groove in the ring clamp locks it into place against the bench pin for safety and stability as you work.

An 80 grit ½” x ½” abrasive band and mandrel (drum arbor) works well for this modification. Draw a reference line on the ring clamp about 10mm from the end. Use the abrasive band to create a two-millimeter indentation around the ring clamp. Test the groove against your bench pin(s) and make adjustments as necessary so the clamp locks in place.This simple modification will make your tool more stable and reduce the chance of damaged jewelry or injury.

.jpg)