Bench Tip #9: Use the Touchstone Method for Testing Purity in Karat Gold

Touchstone method

There are a few scientific methods for precisely determining karat gold purity, some destructive (fire assay) and others nondestructive (X-ray fluorescence). Both methods require costly equipment, special procedures and a well-lit and ventilated area. A simpler method for determining gold purity in jewelry is the “touchstone” testing process, an age-old technique that is relatively nondestructive to jewelry and offers quick results.Use with care: Touchstone testing incorporates the use of acids, so pay close attention to safety. Careful procedures are a must.

Touchstone testing is based on the fact that 24k gold resists all but the strongest acids. The purer the gold, the stronger the acid required to dissolve it. Measured strengths of nitric acid are used to test for 14k and lower. Aqua regia, a mixture of one part nitric acid and three parts hydrochloric acid, is used to test higher karat purity through the process of comparison and elimination.

To conduct touchstone testing, you’ll need an acid testing kit (available through jewelry tool suppliers), a well-ventilated area, two glass beakers, water, baking soda, protective gloves, 320-grit abrasive paper, safety goggles, and paper towels.

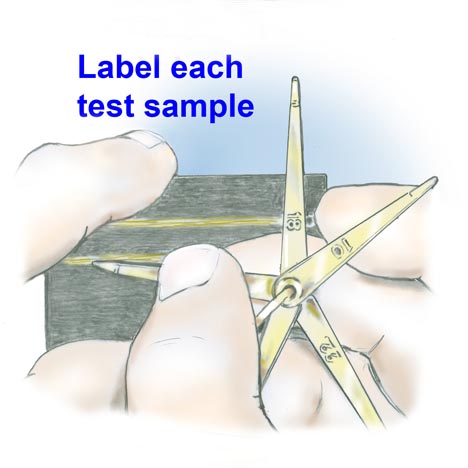

Your testing kit includes a set of testing needles. Each needle has a karat gold sample on its tip and the karat value stamped on the side. Use yellow gold needles for testing yellow gold, and white gold needles for testing white gold.

Each known test sample is labeled on the needle. Rub the known samples onto the stone and label each on the testing stone.

Begin by checking the gold jewelry piece for other stampings (e.g., quality marks or manufacturer’s marks) and make note of characteristics such as heft, color and reflectivity. If you suspect the item may not be gold, use an engraving tool and make a small notch in an unobtrusive place on the jewelry to expose fresh metal. Next, put on protective gloves and place a drop of acid from the 18k gold testing bottle over the small notch. A highly effervescent green reaction indicates base metal, and no further testing is required.If there is little or no reaction, the piece is likely karat gold, and the next test is for purity. Follow these steps:

• Rub the jewelry of unknown karat purity gently back and forth on the testing stone to leave a thin, but clearly visible, metal sample. Use care to take this sample from a place not clearly visible on the jewelry and away from solder joints.

• With a testing needle, draw a question mark on the touchstone that represents the unknown metal.

• Start with the 14k testing needle and rub a layer next to the unknown. Label it “14.”

• Repeat this process, making a layer and then labeling with the 18k, 22k, and 10k testing needles. Now choose the bottle labeled for testing 10k and lightly swipe the applicator across all the samples.

• After approximately 20 to 40 seconds, place the touchstone in a mixture of baking soda and water to neutralize the acid in one beaker, then rinse in water in the other beaker.

• Blot the touchstone with paper towels and observe. The 10k sample has dissolved, but the unknown metal is still visible. This confirms the unknown metal is finer than 10k.

• Next, choose the bottle labeled for testing 14k and swipe it across the samples just below the first test.

• Allow enough time for the acid to react and neutralize, then rinse and blot the touchstone and observe. The acid has dissolved both the 10k and 14k samples. The unknown metal is therefore 14-karat or slightly higher.

Analyze the test results to determine the karatage.

Always prepare the touchstone for its next use by cleaning it thoroughly. Remove the metal from the stone’s surface by placing it facedown on a piece of 320-grit abrasive paper on a flat surface. Apply moderate pressure and sand it in a circular motion until sample layers are no longer visible. Neutralize, rinse and blot dry before replacing in the kit. Always follow the manufacturer’s directions for the proper care, storage and handling of acids