An Introduction to Gem Treatments

As a consumer, you will regularly encounter in the marketplace gems that have been treated to change their appearance. A topic that often comes up is whether a particular gemstone is or isn’t treated. In a sense, humans alter all gem materials after they are found in the earth in order to prepare them for use in jewelry. Natural gem crystals are transformed from their rough crystallographic form into the shapes, outlines, and degrees of polish in the gemstones that we appreciate and wear in jewelry. These steps are and have always been the routine procedures used for manufacturing gemstones. Beyond traditional cutting and polishing, however, gems can often be treated in ways meant to alter their color or clarity. In addition to enhancing their appearance, the process may also improve (or in some cases diminish) the gem’s durability. Because these treatments are not always apparent to the unpracticed eye, and are sometimes difficult to distinguish even by experts, it is necessary and legally required for anyone selling a gem (including consumer to consumer trade) to disclose the treatment procedure it may have received.

Non-disclosure of this treatment could cause a person to believe that a particular gemstone was of higher quality naturally and therefore be more valuable than it actually is. An added challenge is that treatments can be permanent, long lasting, or short-lived under normal jewelry use. Treated gems may require special care by their owner. In the United States, the Federal Trade Commission has established a set of consumer guidelines outlining the need for treatment disclosures and special care requirements, and countries around the world either adhere to similar guidelines, or have regulations of their own. Additionally there are several professional organizations such as the American Gem Trade Association (AGTA), or the International Colored Gemstone Association (ICA), or The World Jewellery Confederation (CIBJO), that have formulated specific guidelines that their members are required to follow regarding the disclosure of treatments in gem materials. The following glossary includes terms that are often used in the gem treatment nomenclature, and that you may encounter when shopping for gemstones. Finally, treatments for gemstones are constantly being changed and refined, and the detection of these new treated gems is an important part of ongoing gemological research.

The following guide will give a short description of the treatment process, some gems for which the process is used, how easy or difficult the treatment is to detect for a trained gemologist, how often the treated gem might be encountered in the jewelry trade, and how durable the material is to normal handling procedures. Any special care instructions for these treated gems are also provided.

Bleaching

– a chemical used to alter / reduce a component of, or the entire color, of a porous gem. Some gemstones are bleached and then dyed, a form of “combination treatment.”

1. The most commonly encountered bleached gems include:

Jadeite jade – Jadeite is often bleached with acid to remove an unwanted brown component from the material. Bleaching in jade is typically part of a two-step process: because acid bleaching causes the material to become slightly porous or susceptible to breakage along fractures, it is then subsequently treated with polymer impregnation to fill these open spaces to produce a better overall appearance.

These sections of jadeite show the material as it looks before and after bleaching.

Pearls – All types of pearls are routinely bleached with hydrogen peroxide to lighten and improve their uniformity of color.

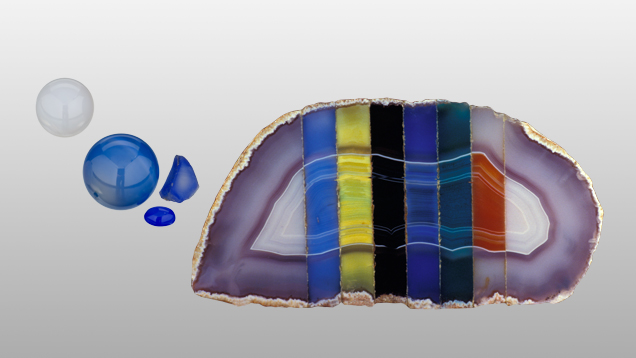

Other materials – Some coral, chalcedony and tiger’s eye quartz may be bleached to lighten their color.

2. Detectability – Bleaching as a one-step process is virtually impossible to detect in most cases. The second step, impregnation with polymer compounds, is easier to detect by a qualified gemological laboratory using magnification and more advanced analytical techniques.

3. Encountered in the trade – Frequently in pearls and jadeite.

4. Durability factors – Acid bleaching causes a breakdown in the structure of most materials, so as a stand-alone treatment, leaves materials vulnerable to breakage. Most bleaching is followed by impregnation to improve durability and strengthen perceived color

5. Special care requirements – Bleached gems tend to be more brittle, and they may be much more porous and thereby more absorbent of human oils and other liquids. It is suggested that pearls be kept in a soft, dry environment to avoid surface damage.

Surface Coating

– altering a gem’s appearance by applying a coloring agent like paint to the back surfaces of gems (a treatment known as “backing”), or paint applied as a coating to all or a portion of a gemstone’s surface with the effect of altering the color.

1. The most commonly encountered coated gems include: Diamonds – Thin-film coatings are sometimes used on diamonds to change their color. Crude, yet effective coatings can also include the use of permanent ink markers along the girdle surface of a diamond, causing its face–up appearance to be affected by the color of the ink used. More modern coating methods use metal oxide thin films.

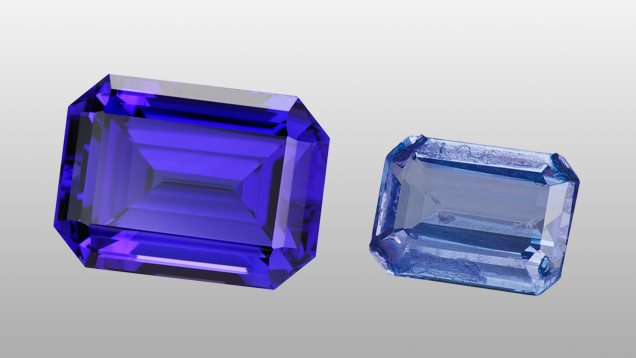

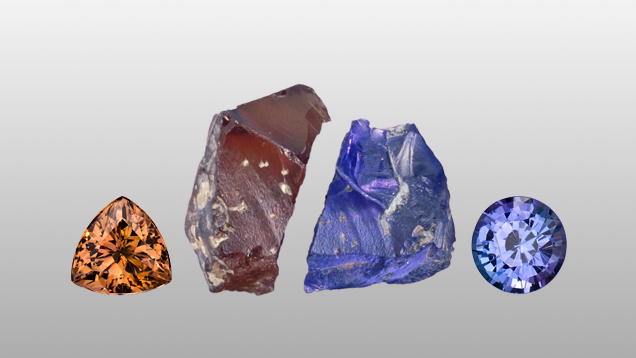

Tanzanite – Though rarely used, tanzanites have been coated to improve the intensity of their blue-violet color.

Topaz – Some colorless topaz is coated with metal oxides to create the appearance of a variety of different colors. In the past, such treatments were often described as a form of “diffusion” of a chemical into the surface of the gemstone, but this was a misnomer since in most cases the added color was confined to the surface of the gemstone.

Coral – Some black coral (also known as Horn coral) has been reported as bleached and then coated with relatively thick layers of artificial resin with the goal of protecting the coral and intensifying its color.

Pearls – Some pearls reportedly have been treated with a colorless hard coating in an effort to improve durability.

Quartz – Occasionally, quartz is coated with metal oxides to create colors rarely seen in natural quartz.

2. Durability factors – Because they tend to be softer than or may not adhere well to the underlying gem, thin-film surface coatings of any kind are susceptible to scratching, particularly along facet edges and junctions. Care should be taken to not allow any hard or abrasive objects to come in contact with coated gems.

3. Detectability - Once suspected, the treatment is easy to identify by a skilled gemologist except in the situation where the coating substance is colorless, and it has been added to improve durability.

4. Encountered in the trade – Occasionally for some gems. 5. Special care requirements – When they are not being worn, coated gem materials should be wrapped in soft packaging and kept in a dry environment.

Dyeing

– introducing colored dyes into porous or fractured gems to change their color. Such fractures are sometimes purposely induced by heating the gem so that an otherwise non-porous material can more readily accept the dye.

1. The most commonly encountered dyed gems include:

Pearls – Dye often improves the appearance of lower–quality natural and cultured pearls by enhancing their color.

Other gem materials – The process has been used since ancient times for materials such as coral, turquoise, lapis lazuli, howlite, nephrite jade, chalcedony, quartz, emerald, and ruby.

2. Durability factors – When dye is applied to porous materials, their durability may be long-lived but is ultimately dependent on the stability of the dye itself. In gems with larger fractures, the dye can sometimes leak out under a variety of conditions. Many dyes can be removed if the gem comes into contact with a solvent such as alcohol or acetone. Some dyes are unstable with exposure to the ultraviolet in sunlight and can fade over time.

3. Detectability –A qualified gemologist can detect dyed gems in most cases.

4. Encountered in the trade – Occasionally for most gems, and frequently for colored pearls.

5. Special care requirements – When it is known that gem materials have been dyed, care must be taken to not bring them in contact with chemicals such as acetone or alcohol, which could dissolve the dyes, or have them exposed to prolonged periods of sunlight (such as leaving it on a sunny window ledge) which could cause the dyed colors to fade.

Fracture or cavity filling

– filling surface-reaching fractures or cavities with a glass, resin, wax or oil to conceal their visibility and to improve the apparent clarity of gem materials, appearance, stability, or in extreme cases—to add to a slight amount of weight to a gem. The filling materials vary from being solids (a glass) to liquids (oils), and in most cases, they are colorless (colored filler materials could be classified as dyes).

1. The most commonly encountered fracture-filled gems include:

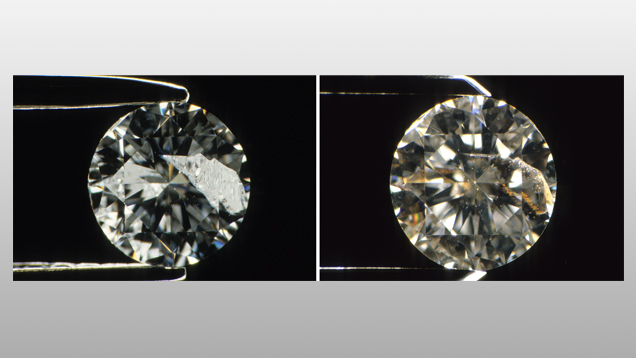

Diamond – Surface-reaching fractures are sometimes filled with high-lead-content glass. This reduces the visibility of the fracture, with the goal of enhancing the appearance of the diamond. The filled fracture is still present – it is just less apparent.

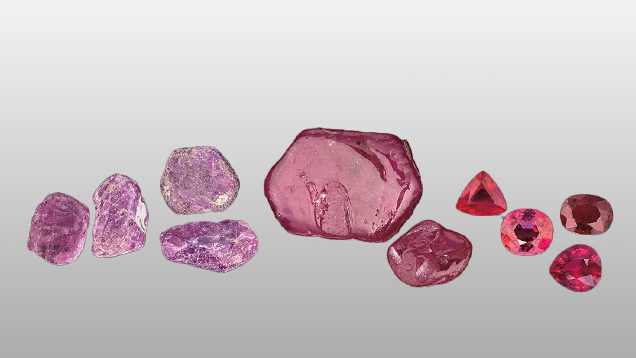

Ruby – Numerous surface-reaching fractures are filled with a glass to lessen their visibility and make the gem more transparent than it really is. In some cases, the amount of filler glass can be significant in a treated ruby.

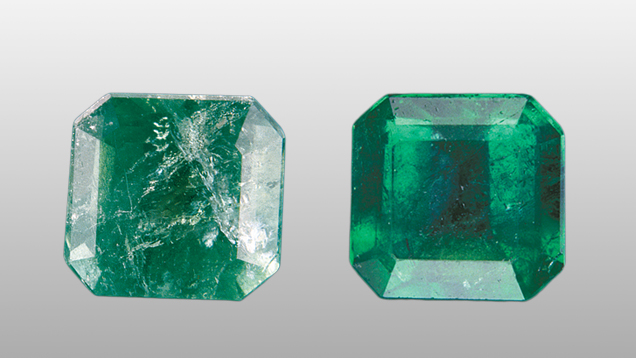

Emerald – Surface-reaching fractures in emerald are sometimes filled with essential oils, other oils, waxes, and “artificial resins” —epoxy prepolymers, other prepolymers (including UV-setting adhesives), and polymers to reduce the visibility of the fractures and improve the apparent clarity. These substances have varying degrees of stability in treated emeralds, and the volume of filler material present can range from insignificant to major amounts.

Other materials – Resins and glasses can potentially be used on any durable gem with surface-reaching fractures, including quartz, aquamarine, topaz, tourmaline and other transparent gems. This kind of treatment is, however, less prevalent than the other treatment processes mentioned above.

2. Durability factors – Much depends on the durability of the filler. Glasses tend to be harder and therefore more durable than resins, oils or waxes. Changes in air pressure, proximity to heat, or by exposure to chemicals can all affect the appearance of filled gems by potentially altering or removing the filler substance.

3. Detectability – In most cases, filled gems can be recognized by a qualified gemologist using magnification.

4. Encountered in the trade – Often encountered for diamonds, ruby and sapphires, and emerald.

5. Special care requirements –Avoid exposure to heat, and changes in air pressure (such as in an airline cabin), or chemicals. Filled emeralds can also be damaged by exposure to hot water used for washing dishes.

Heat Treatment

– the exposure of a gem to high temperatures for the purpose of altering its color and/or clarity.

1. The most commonly encountered heat-treated gems include.

Amber – When amber is submerged in hot oil—linseed oil for example—it's inherent body color can darken, and the material can take on a clearer appearance. The hot oil can also cause the material to develop a series of spangled, glittery inclusions.

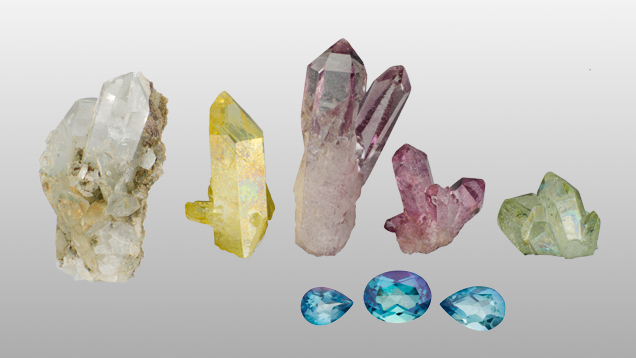

Amethyst – Heating can remove unwanted brownish inclusions in some amethysts or lighten the color of overly dark stones.

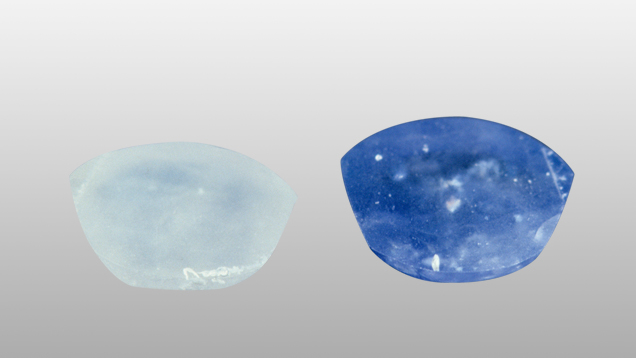

Aquamarine – Without treatment, much of the aquamarine is blue–green in coloration. Heating in a controlled environment can remove the greenish color component from the material to produce a more blue appearance.

Citrine – Some forms of amethyst can be heated and turned into citrine.

Ruby – Heating can remove purplish coloration rendering a more pure red color. The process can also remove “silk” (minute needle–like inclusions) that can cause a gem to appear lighter in tone and be more opaque. Heating can also cause recrystallization of the silk inclusions to make them more prominent which allows the gemstone to have stronger asterism (a reflecting star effect).

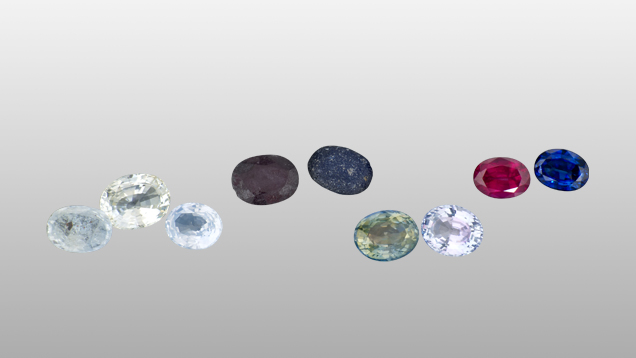

Sapphire – Heating can intensify, or even induce, a blue coloration in sapphires. The heating can also remove “silk” inclusions, which also helps to make the material appear more transparent. It can also cause recrystallization of the silk inclusions to make them more prominent, which allows the gemstone to have stronger asterism (a reflecting star effect).

Tanzanite – The mineral zoisite, which includes the gem variety known as tanzanite, it is often heated at low temperatures to remove a brownish color component to produce a stronger purplish-blue color.

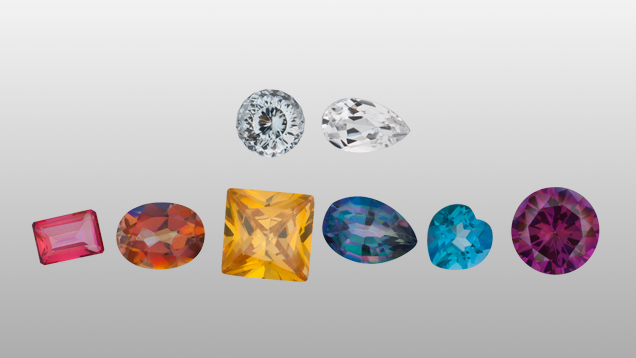

Topaz – Heating yellowish pink topaz sometimes has the effect of removing the yellowish color component, thereby intensifying the pink color. Heating is also used to control the color of blue topaz—the material that may have started out as colorless is irradiated followed by heating which results in a desirable blue color.

Tourmaline – Sometimes heat treating can cause overly dark green material to become lighter in tone, or it may affect the color in other tourmalines.

Zircon – Some reddish brown zircons are heated in controlled environments to produce more commercially viable colors, including an intense blue.

2. Durability factors – Heat treatments in all of the gemstones mentioned above are considered durable and permanent under normal handling conditions.

3. Special care requirements – Submitting gemstones to intense heat may render them slightly more brittle than usual, and care must be taken not to damage pointed faceted corners and edges.

High pressure, high temperature (HPHT) treatment

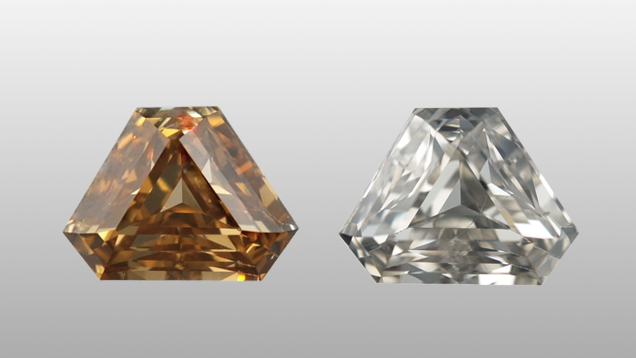

– Heating a diamond to high temperatures under high confining pressures to remove, or change its color.

Heating diamonds at high pressures and high temperatures can remove or lessen their brownish coloration so the gem becomes colorless. Other types of diamonds may be transformed from brown to yellow, orangy yellow and yellowish green, or to blue colors by this process.

1. Durability factors – HPHT treatments are considered stable and permanent to normal jewelry handling conditions.

2. Detectability – Difficult to identify, even by seasoned gemologists. If suspected, only a qualified gemological laboratory can confirm the treatment.

3. Encountered in the trade – Occasionally in colorless diamonds, more readily in some colored diamonds.

4. Special care requirements – Other than normal care considerations used for most jewelry, there are no particular instructions for the care and handling of HPHT treated diamonds.

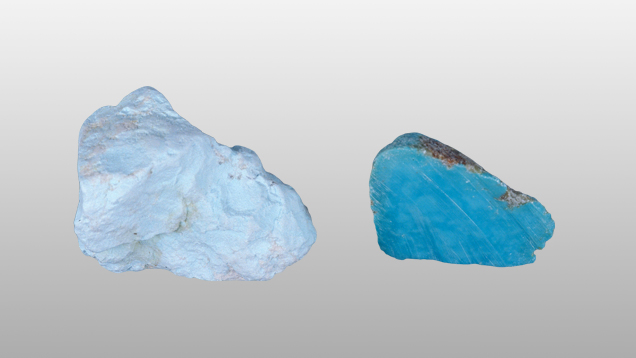

Impregnation

– the surface of a porous gemstone is permeated with a polymer, wax or plastic to give it greater durability and improve its appearance.

The most commonly encountered wax or plastic impregnated gemstones are opaque, and they include turquoise, lapis lazuli, jadeite, nephrite, amazonite, rhodochrosite and serpentine.

1. Durability factors – Many impregnations are often “skin deep” and due to the melting point of plastic and wax, can be susceptible to heat damage. Plastic impregnations are considered durable in gem materials such as turquoise as long as they are not subjected to heat or chemicals.

2. Detectability – In most instances a qualified gemologist can readily identify the treatment.

3. Encountered in the trade – Frequently seen in the trade.

4. Special care requirements – Care must be taken not to subject gemstones with wax or plastic impregnations to heat, such as that encountered by a jeweler’s torch, since these will likely damage the material.

Irradiation

– exposure of a gem to an artificial source of radiation to change its color. This is sometimes followed by a heat treatment to further modify the color. This second step also known as a “combination treatment.

1. The most commonly encountered irradiated gems include:

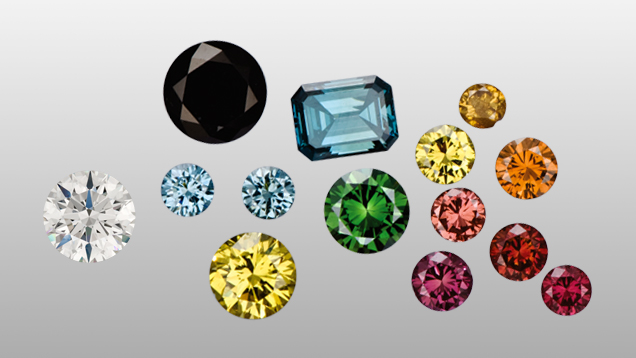

Diamond – Neutron and electron radiation are the most common forms of artificial irradiation, and it is possible to induce black, green, blue green, deep yellow, orange, pink and red diamonds (often combined with a secondary step of heating, to achieve certain colors).

Corundum – Some bright orange colors are induced in sapphires with a pale yellow natural color. The color in these is not stable and fades upon exposure to light.

Topaz – colorless topaz has little commercial value in the gem market today, but it can be subjected to artificial radiation to dramatically change its color. Used in conjunction with heat treatment, a variety of strong blue colors can be achieved for topaz.

Pearl – Some pearls are irradiated resulting in dark gray colors.

Quartz – Varieties of quartz may be irradiated to produce amethyst, and some combination treatments that include heating after irradiation resulted in green quartz.

Other gems – Some varieties of beryl and spodumene can be irradiated to deepen an inherent color, or change the color altogether.

2. Durability factors – some irradiated gems’ color fades upon exposure to strong light. Blue topaz, diamond and quartz tend to have very stable colors as long as they are not exposed to high temperatures (this is especially true for irradiated colored diamonds, whose colors may be damaged if the diamond is exposed to the heat of a jeweler’s torch during jewelry repair procedures).

3. Detectability – Because strong blue colors do not occur naturally in topaz, such stones are considered to have undergone irradiation treatment. Strong colors in green, pink, and red diamonds should also be considered suspect. Determination whether a colored diamond is natural color or treated color requires examination by an experienced gem-testing laboratory.

4. Encountered in the trade – Extremely frequent for topaz, and frequent in fancy color diamonds.

5. Special care requirements – In the beryl and spodumene gemstones, the irradiated color tends to be short lived and fades upon exposure to bright light. Otherwise, there are no special care requirements for most irradiated gem materials.

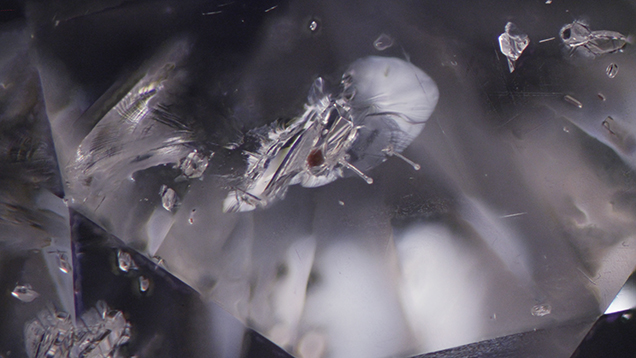

Laser drilling

– this involves using a narrow focused beam of laser light to burn an open channel from the surface of a diamond to reach dark inclusions. This is generally followed by the use of a chemical forced into the channel to dissolve or alter the appearance of the inclusion.

Diamonds are the only gemstones to be treated in this fashion, in part because only they can withstand the heat of a laser.

1. Durability factors – While lasers could potentially affect the structure of a diamond, most laser drill holes are microscopic, and the durability of the diamond does not come into play.

2. Detectability – Easily detectable by most gemologists and qualified gemological laboratories because of the presence of the laser drill holes.

3. Encountered in the trade – Sometimes.

4. Special care requirements – There are no special care requirements for laser-drilled diamonds.

Lattice diffusion

– the penetration of certain elements into the atomic lattice of a gemstone during heat treatment, with the objective of changing or accentuating its color.

1. The most commonly encountered diffused gems include:

Corundum (ruby and sapphire) – while experimentation during the 1980s concentrated on diffusion of titanium and chromium (which are coloring agents in corundum), the ability to fully penetrate the stone with color met with little success. In 2003, very strongly colored sapphires began to appear in the market, and diffusion was again suspected. It was found that it was diffusion — but of a new element: beryllium. Beryllium which has a much smaller atom than titanium or chromium, was able to diffuse all the way through a sapphire; even large sapphires, successfully changing their color. It was soon found that the color of rubies could be accentuated as well using this treatment process.

Feldspar – Varieties of feldspar, notably andesine and labradorite were found to be receptive to the diffusion of copper, completely altering their color.

Other materials – There have been reports of diffusion to cause color alterations in both tourmaline and tsavorite (a variety of garnet) but the claims have not been substantiated.

2. Durability factors – The treatment is considered permanent.

3. Detectability – Extremely difficult to detect with certainty in many instances—and if so, only by qualified laboratories.

4. Encountered in the trade – Diffusion treated corundum is widespread in the trade.

5. Special care requirements – There are no special care requirements for diffusion treated corundum or feldspar.

.jpg)