Montana’s Gem Mountain Sapphire Mine: Sharing the Excitement of Mining with the Public

June 3, 2016

INTRODUCTION

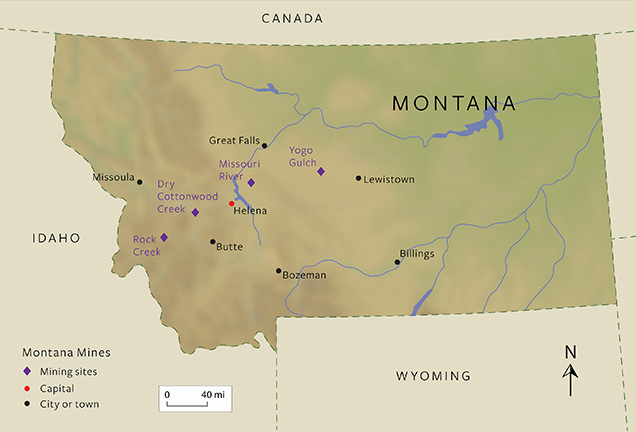

Hidden in the mountains of the Treasure State, Gem Mountain Sapphire Mine is a worthwhile travel destination for catching the incurable Montana sapphire fever. Sapphire deposits in this area are some of the richest in North America. Sapphire found here is usually referred to as Rock Creek sapphire.

Like many other sapphire deposits in Montana, the Rock Creek deposit was discovered by gold prospectors and first mined around 1892. Following World War II, businesses bringing rock hounds to dig sapphires by hand started to develop in the Gem Mountain area. Today visitors can also drop by the sapphire jewelry stores in the nearby town of Phillipsburg. From pulling a sapphire out of the dirt to setting it in a piece of jewelry, they can enjoy the excitement and accomplishment of treasure hunting in one place. Gem Mountain Sapphire Mine offers these services to passionate tourists looking for treasure. A GIA team of members from both Education and Lab Services visited the mine and witnessed the entire Montana sapphire mine-to-market process.

The mine’s previous owners formally opened the Chausee Sapphire Mine in the mid 1960s and changed the name to Gem Mountain in the early 1980s. In 2001 Gem Mountain acquired the holdings of American Gem Corporation and began mining at Anaconda Bench.

HEAT TREATMENT OF ROCK CREEK SAPPHIRE

Gem Mountain offers a variety of services, including heat treatment of sapphires found by customers to add beauty and enhance value. Gem Mountain is one of only two companies in North America that offer this service. Occasionally customers bring stones from sources other than Rock Creek to be treated based on in-person evaluation.

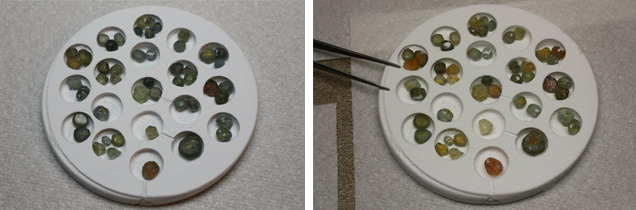

After customers find rough sapphires, it is recommended that they have them evaluated on-site. The appraiser goes through the stones on a light table to choose rough stones of at least a half carat with no obvious cracks or flaws. The selected stones are then evaluated under magnification to determine whether they are suitable for heat treatment or can be faceted as is. Magnification helps to show the fractures and flaws better to identify any durability concerns. Some stones are labeled “no replacement guaranteed” or simply removed from the group of candidates. Stones not suitable for further processing are returned to the customers to be kept as souvenirs.

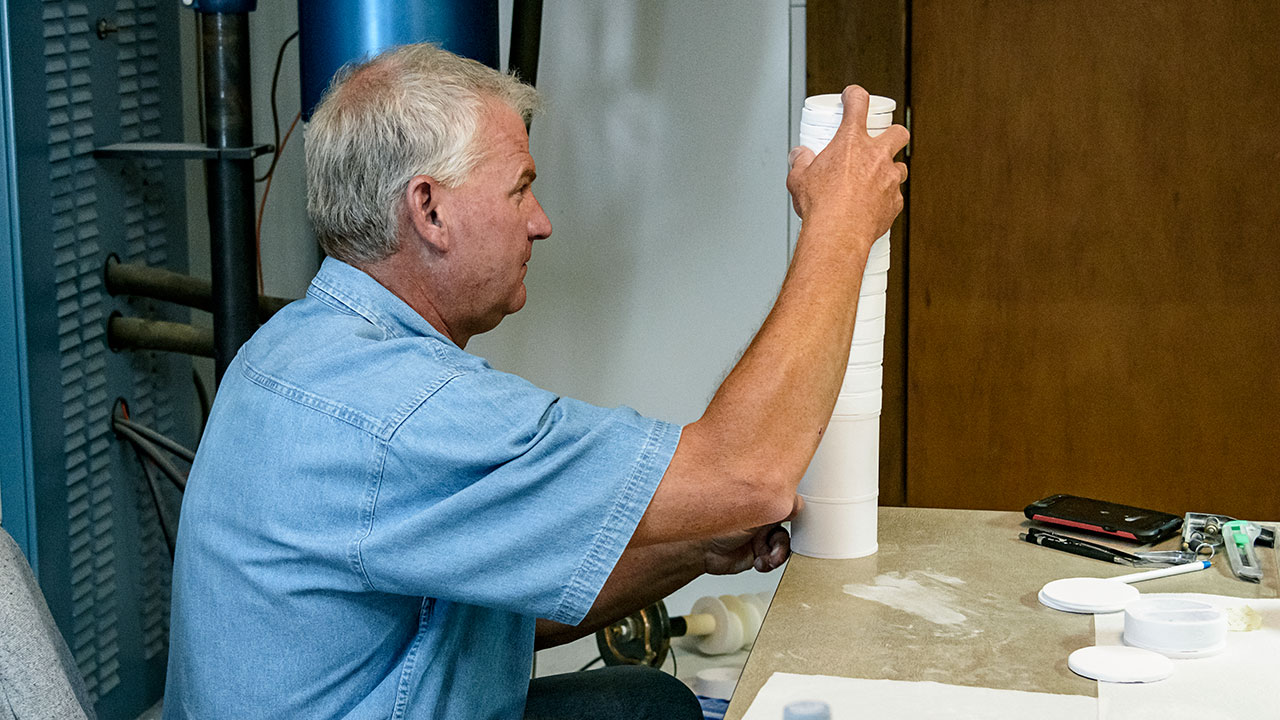

Chris Cooney has developed sophisticated tracking and numbering systems to avoid mixing. Stones suitable for heat treatment are packaged well, with the customers’ information recorded.

Chris Cooney, the owner of Gem Mountain Sapphire Mine, guided the GIA team through the heat treatment process and shared the details of color grading, stone loading, heating environment, and cutting options. (If you are interested in the process and want to know more about suggested improvements to certain starter materials, please watch this video.)

All stones go through a two-step heat treatment to maximize their value. The first step is the fancy burn, which is done in an oxygen-rich environment. Pure oxygen is forced into the furnace. Permeable aluminum oxide crucibles of different capacities are used as stone holders. After the fancy burn, Chris examines the stones to determine whether the fancy color will satisfy the clients or the stones need to go through a second heating process called the blue burn. The majority of the stones will become yellowish or brownish to a degree, and whether the color is accepted by customers is quite critical. Color evaluation is a very time- and energy-consuming process.

batch to skip the blue burn. Photo by Andrew Lucas/GIA.

Sapphires that do not acquire good fancy colors will undergo the blue burn, which is done in a reducing environment. Carbon dioxide and hydrogen are pumped into the furnace to generate this environment. According to Chris, about 40 to 45 percent of the stones will receive a nice saturated blue color after the blue burn, while the majority will fall into the teal blue range, with a noticeable green hint. Some green stones have a readily available market.

Color is the most subjective factor in gemstone evaluation. Each year Gem Mountain processes tens of thousands of sapphires for its customers. Chris said ideally his clients would grade color by themselves since each one has a different preference. But while color evaluation puts a lot of pressure on the practitioners, it is a service that distinguishes Gem Mountain from other sapphire businesses.

BUSINESS MODEL AND PASSION

For the past hundred years sapphire mining has not been uncommon in Montana, and the current production is consumed predominantly by tourists. While most businesses offer sapphire gravel washing, they need to provide some special service to deliver an extraordinary experience.

The excitement of searching for sapphire and quality family time are two of the most important things that Chris Cooney and his staff want to deliver to the public. He enjoys seeing happy customers spend quality time with their families and often jokes that he works in the entertainment business.

about her experience at Gem Mountain. Photo by Andrew Lucas/GIA.

Gem Mountain is a complete mine-to-market sapphire business. Miners get the sapphire-bearing concentrates directly from the mine at Anaconda Bench and bring them to the washing site and the store in town, where visitors wash and screen the gravel to search for sapphires. Customers can have the rough sapphire evaluated, heat treated, faceted, and even mounted in jewelry. In the Gem Mountain store we also saw hats and T-shirts featuring the Gem Mountain logo and sapphire mining. Gem Mountain recently developed this line of products, which turned out to be quite popular and profitable and are also sold online.

At Gem Mountain the GIA team washed sapphire just like real customers. We saw the excitement and passion on the visitors’ smiling faces. Brothers and sisters, parents and kids were all dedicated in their search. We enjoyed hearing the excited screams of people clustering around one table to share a moment. Staff members are passionate and very patient in teaching the visitors washing techniques. We were also impressed that at the end of each day all the washing facilities and tools are well cleaned and organized.

Along with the washing site next to the mine, Gem Mountain runs its own retail store in Phillipsburg featuring sapphire jewelry and souvenirs. Customers can have their stones sent to Sri Lanka to be cut, but many choose to have them cut and mounted in Montana to support the local economy.

EVERLASTING EXCITEMENT

During our visit some customers showed us spectacular sapphire jewelry made with stones found at Gem Mountain. Some of the sapphires had been heat treated, while many were naturally good colors. These customers had visited the mine repeatedly over many years with family and friends. Their collections were quite impressive even from a professional perspective.

The GIA team interviewed a family about their Gem Mountain sapphire-hunting experience over the years. They have become quite professional at searching for sapphire and can give newcomers a lot of guidance. The testimony of multiple customers is the best reward for Chris Cooney and his staff at Gem Mountain.

Dr. Tao Hsu is technical editor of Gems & Gemology. Andrew Lucas is manager of field gemology for education, Shane McClure is the global director of colored stone services, and Kevin Schumacher is the digital resources specialist at GIA Carlsbad.

DISCLAIMER

GIA staff often visit mines, manufacturers, retailers and others in the gem and jewelry industry for research purposes and to gain insight into the marketplace. GIA appreciates the access and information provided during these visits. These visits and any resulting articles or publications should not be taken or used as an endorsement.

The authors would like to thank Robert Kane, CEO of Fine Gems International, for facilitating our visit to Gem Mountain. We also highly appreciate the help of Chris Cooney and Gem Mountain’s passionate staff.